Lubricants and Lubrication

Lubricant

A lubricant

(sometimes shortened to lube) is a substance that helps to reduce friction

between surfaces in mutual contact, which ultimately reduces the heat generated

when the surfaces move. It may also have the function of transmitting forces,

transporting foreign particles, or heating or cooling the surfaces.

The main features

of lubrication are:

·

It reduces wear and tear and surface deformation, by avoiding

direct contact between the rubbing surfaces.

·

It reduces the loss of energy in the form of heat by acting as a

coolant.

·

It reduces the efficiency of the machine by reducing the waste of

energy.

·

It reduces expansion of metal by local frictional heat.

Classification

of lubricants

On the basis of

state, lubricants are classified as solid, semi-solid and liquid lubricants.

Solid

Lubricants

A solid lubricant

is a material used as powder or thin film to provide protection from damage

during relative movement and to reduce friction and wear. Solid lubrication is

often termed as dry lubrication. The main purpose of solid lubricants is to

build up a continuous adherent soft or hard film in the rubbing surfaces. Most

commonly used solid lubricants are talc, mica, tungsten sulphide, etc. Solid

lubricants are mainly used as additives to oils and greases. Solid lubricants

are used where:

(i) operating

conditions are such that a lubricating film cannot be secured by use of

lubricating oils or greases;

(ii) contamination

(by the entry of dust or grit particles) of lubricating oil or grease is

unacceptable,

(iii) the operating

temperatures or load is too high even for a semi-solid lubricant to remain in

position; and

(iv) combustible

lubricants must be avoided.

Semi-solid

Lubricants

Semi-solid

lubricants are a gel-like substance which reduced friction between two moving

surfaces. The petroleum products such as

grease, Vaseline and waxes which are neither solid nor liquid at ordinary

temperature are most important semi-solid lubricants. Grease is prepared from

the mixture of petroleum, oil and soaps.

Liquid lubricants

It includes animal oils, vegetable oils, petroleum oils, synthetic

lubricants.

Animal oils: tallow oil, whale oil etc.

Vegetable oils: castor oil, palm oil etc

Petroleum oils: petroleum fractions

Synthetic lubricants: polyglycol, silicones etc.

Application of Lubricants

·

Lubricants are primarily used to

reduce the friction between two moving surface.

·

Rust and corrosion inhibitors

·

Used in the soap and paint

industries.

·

Liquid lubricants are used in

medicines

·

Lubricants are also used as cutting

fluid in cutting, grinding, drilling of metals.

·

Used as anti-wear, antioxidants, and

antifoaming agents.

Function of lubricants

·

Keep surfaces separate under all

loads, temperatures and speeds, thus minimising friction and wear.

·

Act as a cooling fluid removing the

heat produced by friction or from external sources.

·

Remain adequately stable in order to

guarantee constant behaviour over the forecasted useful life.

·

Protect surfaces from the attack of

aggressive products formed during operation.

·

Show cleaning capability and dirt

holding capacity in order to remove residue and debris that may form during

operation.

Mechanism of lubrication

Fluid film lubrication

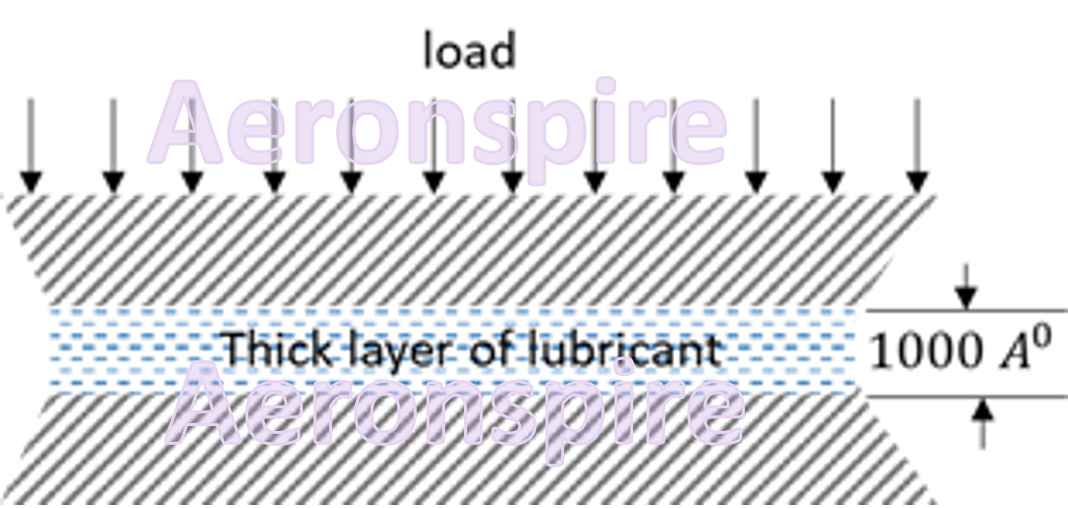

It is also known as thick film or hydrodynamic lubrication. It is

carried out with the help of liquid lubricants. In this mechanism, two moving

and sliding surfaces are separated by thick film of lubricant fluid of about

1000A°, applied to prevent direct surface to surface contact and consequently

reduce wearing and tearing of metals. Therefore, it is known as thick film or

fluid film lubrication or hydrodynamic (hydro meaning liquid and dynamic

meaning relative motion) lubrication. In this case fluid is formed by mixing of

hydrocarbon oils and anti-oxidants with long chain polymer so as to maintain

viscosity. Fluid film lubrication is useful in delicate and light machines like

watches, clocks, guns, scientific equipments.

Boundary lubrication

It is also known as thin film lubrication.) Thin Film or Boundary

Lubrication. It is carried out with semi-solid (grease) and solid (graphite and

molybdenum disulphide) lubricants. Boundary lubrication is a condition in which

the lubricant film becomes too thin to provide total separation. In this type

of lubrication, a thin film of lubricant is adsorbed on the surface by weak

Vander Waals forces. Thin film lubrication is operating at relatively low speed

and heavy loading (pressure).

Extreme Pressure (or Temperature) Lubrication

In this mechanism, moving or sliding surfaces are under high

pressure and speed, therefore this is known as extreme pressure lubrication. In

such a case high temperatures generated due to friction, under these condition

liquid lubricants are fail to stick and decompose or vaporize. These problems

are minimized by special additives are added to mineral oils. These additives

form durable films on metal surfaces which can withstand high loads and high

temperatures. Important additives are organic compound having group like

chloride, sulphur, phosphorus etc. They react with metallic surface to form

metallic compound (possess high melting points and serve as good lubricants

under extreme temperatures and pressures) like chlorides, sulphides, phosphate

as more durable film.

Physical characteristics of lubricants

Lubricants have a wide range of properties that impact their

physical and chemical properties. Knowing about these properties is important

in determining which lubricant is best for which situation. While there are

many properties, the most important are:

Viscosity: A lubricant’s

internal resistance to flow. Higher viscosity lubricants are thick and don’t

flow, while lower viscosity lubricants have a closer consistency to water and

do flow. The image below demonstrates the viscosity of four different oils.

The ball sinks faster in the thinner, low viscosity oil while it sinks slower

in the higher viscosity blends.

Viscosity Index: The rate of change in viscosity with changes in temperature. In

other words, how much viscosity changes as temperature changes.

Oxidation Stability: Oxidation is a reaction that occurs when oxygen is combined with

lubricating oil. Variables such as high temperatures, water and acids will

accelerate the rate of oxidation. The life of a lubricant is reduced as

temperatures increase, leading to varnish and sludge.

Pour Point: The lowest

temperature at which a lubricant will flow or pour like a liquid. This can

differ depending on test conditions.

Demulsibility: The ability

of a lubricant to separate from water.

Oiliness: Oiliness of a

lubricant is a measure of its capacity to stick on to the surface of machine

parts, under conditions of heavy pressure or load.

Volatility: The

volatility of a lubricant is the property that defines its evaporative loss

characteristics. The more volatile a lubricant is, the lower the temperature at

which smaller hydrocarbon molecules will be driven off or evaporated.

Flash and fire point: Flash point is the lowest temperature at which the vapor produced

by continuous heating of lubricants can be ignited. Fire point is the lowest

temperature at which not momentary ignition but continuous ignition is

possible.

Cloud & pour point: When the lubricant oil is cooled slowly, the temperature at which

it becomes cloudy or hazy in appearance, is called its cloud point; while the

temperature at which the lubricant oil cease to flow or pour, is called its

pour point.

Chemical characteristic of point

Acid value or neutralization number: It is an indication of the

acidity or alkalinity of an oil; neutralization number is the number is the

weight in milligrams of the amount of acid (hydrochloric acid) or base

(potassium hydroxide) required to neutralize one gram of the oil.

Emulsification: It is the

property of oils to get intimately mixed with water, forming a mixture, called

emulsion.

Saponification value: The saponification value is defined as the number of milligrams

of KOH needed to neutralize the fatty acids obtained by complete hydrolysis of

1gram of an oil sample. Fats or oils with high saponification value (such as

coconut and palm oil) are more suitable for soap making.

Selection of lubricants

Lubricants reduce wear and tear and energy loss due to friction.

For various types of machines, depending on their service conditions, different

lubricants are used. Some of them are discussed as follows:

Properties of lubricants: By knowing the properties of lubricant, suitable lubricant must

be selected so that its properties should not change under service conditions.

Lubricants for delicate instruments: lubricants which work perfectly fine at lower temperature are

preferred for delicate instruments. Delicate instruments are not exposed to

higher temperature and hence such lubricants are suitable for delicate

instruments.

Lubricants for gears: Gears are usually subjected to

extreme pressure. Hence lubricants containing extreme pressure additives, good

oiliness are used for lubricants.

Lubricants for cutting tools: Cutting tools experience high friction and generate large amount

of heat. Hence, lubricants used for cutting tools should have cooling

properties. Therefore, mineral oils like fatty acid and chlorinated compound

are used as lubricants.

Lubrication for electrical transformers: Lubricants used in electrical

transformer must possess good dielectric properties and have good heat transfer

properties and should be of low viscosity. Lubricants used for transformer coil

is often referred to as transformer oil.

Characteristic of transformer oil

Transformer oil is basically an insulating oil for transformer. It

is processed from fractional distillation and treatment of crude petroleum.

Transfer oil must possess following characteristics:

·

Excellent dielectric properties so

that it results minimum power loss in transformer.

·

Good insulation across windings.

·

High thermal stability so that is

reduces evaporation losses.

·

Transformer oil should have long

life under severe electrical stress.

·

Transformer oil should provide

protection against corrosion.

·

Transformer oil should have wider

range of operating temperature and should have good cooling capability.