Corrosion

Corrosion is the

term used to describe the process of the surface of metal objects getting

covered by oxides (or) other salts of the metal. It is basically defined as a

natural process that causes the transformation of pure metals into undesirable

substances when they react with substances like water or air. This reaction

causes damage and disintegration of the metal starting from the portion of the

metal exposed to the environment and spreading to the entire bulk of the metal.

Corrosion is

usually an undesirable phenomenon since it negatively affects the desirable

properties of the metal. For example, iron is known to have good tensile

strength and rigidity (especially alloyed with a few other elements). However,

when subjected to rusting, iron objects become brittle, flaky, and structurally

unsound.

Factors Affecting Corrosion

·

Exposure of the metals to air

containing gases like CO2, SO2, SO3 etc.

·

Exposure of metals to moisture

especially salt water

·

Presence of impurities like salt

(eg. NaCl).

·

Temperature: An increase in

temperature increases corrosion.

·

Presence of acid in the atmosphere:

acids can easily accelerate the process of corrosion.

Types of corrosion

Corrosion occurs in many ways depending upon the attack of the

metal, by the surrounding medium. There are two types of corrosion

·

Dry corrosion

·

Wet Corrosion

Dry corrosion

Dry corrosion occurs when metals come in direct contact with atmospheric

gases like O2, CO2 etc. Dry corrosion is hence often

referred to as direct chemical corrosion or atmospheric corrosion. The rate of

corrosion is faster especially near industrial areas as atmospheric air

contains more corrosive gases in industrial area. Dry corrosion is then further

subdivided in

·

Oxidation corrosion

·

Corrosion due to other gases

Oxidation corrosion

Oxidation corrosion is a type of dry corrosion where corrosion

takes place mainly because of presence of O2. Oxygen present in air

directly reacts with metal either at low or high temperatures in the absence of

moisture.

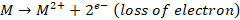

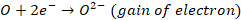

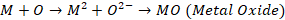

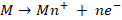

Mechanism of oxidation corrosion

Oxidation corrosion is brought about by direct action of oxygen on

metals by forming oxide film. The mechanism of oxide film formation can be

represented by the following reactions:

Net reaction,

In above reactions, the electrons are transferred from metal atom

to oxygen. Metal losses electrons while oxygen accepts electrons forming their

respective ions. These two types of ions combine together to form metal oxide

layer. Nature of the oxide film formed on the surface of metal plays an

important part in oxidation corrosion process. For further oxidation to

continue a) the metal ion must diffuse outwards or b) oxide ion must diffuse

inwards. Former occurs more readily as because of the smaller size of the metal

ion.

In oxidation corrosion, the nature of the oxide film plays an

important role. It may be

a) Stable A stable layer of

metal oxide is formed which is impervious and this protects the metal from

further corrosion. Eg :- Al, Sn. "If the volume of the oxide film is

greater than the volume of the meta surface, then the oxide layer is protective

and non-porous. On the other hand," if the volume of the metal oxide is

less than the volume of the metal, then the layer is non-protective and

porous". This is known as Pilling-Bed worth rule.

b) Unstable The oxide layer

decomposes back to metal and oxygen.

c) Volatile Oxide layer vaporises

as soon as it is formed. Then by the metal surface is exposed for further

attack. For example, molybdenum oxide

d) Porous Oxide layer has

porous or cracks, so oxygen has access to the underlying metal. Hence, corrosion

continues.

Wet corrosion or electro-chemical corrosion

This type of corrosion occurs at a solid-liquid interface when the

metals are in contact with moist air or any liquid medium. If two dissimilar

metals are dipped in a solution, the solution act as a conducting medium

between them. One of the two metals acts as the anode and the other as a

cathode.

At anode: Oxidation

(Corrosion) takes place i.e.

At cathode: Reduction takes

place, Where electrons are consumed.

Corrosion of an anode is based on how electrons are consumed at

cathode.

At cathode consumption of electron takes place either by

liberation or evolution of hydrogen or by absorption of oxygen. It is also

known as immersed corrosion as it occurs in metal when they are immersed or

dipped in the same solution.

Galvanic corrosion or Bimetallic corrosion- When two dissimilar metals are connected in an electrolyte, the

metal higher in electrochemical series undergoes corrosion. Eg:- Zn and Cu. Zn

acts as anode and is protected & Cu acts as cathode.

Concentration Cell corrosion- It is due to electrochemical attack on the metal surface, exposed

to an electrolyte of varying concentrations or of varying aeration. This may be

the result of local differences in metal ion concentrations.

Differential aeration corrosion- The most common type of concentration cell corrosion occurs when

different parts of the metal are exposed to different O2 or air concentration.

Less oxygenated part acts as anode and undergoes corrosion, whereas more

oxygenated parts acts as cathode.

Protection of metal from corrosion

The various protective measures include

·

Modification of the environment

·

Cathodic protection

·

Use of protective metal coating

Modification of environment

In this method, the metals are protected from corrosion either by

removal of corrosion stimulants or by the use of inhibitors. A corrosion

inhibitor is a substance which when added in small quantities to the aqueous

corrosive environment and effectively decreases the corrosion of the metal.

Cathodic protection

The metal to be protected is forced to behave like cathode, there

by corrosion does not occur.

There are two types of cathodic protection

Sacrificial anodic protection: In this method, the metallic structure (to be protected) is

connected to more anodic material. So, that the corrosion is concentrated at

more active metal. The more active metal sacrifices itself by corrosion and

protects the structure (cathode). The sacrificial anode are Zn, Mg, Al. This

method is mainly used for protection of underground pipeline, cables, and

marine structures.

Impressed current cathodic protection: In this method, an impressed current is applied in opposite

direction to nullify the corrosion current and convert the corroding metal from

anode to cathode. The impressed current is derived from a direct current source

like a battery. Sufficient D.C current is applied to an insoluble anode, buried

in the soil and connected to the metallic structure to be protected. This type

of cathodic protection is applied to open water-box coolers, water-tanks,

buried oil or water pipes etc.

Application of protective coatings

This method is most commonly used method to prevent metal from

corrosion. As its name suggests, a coating is applied over metal so it doesn’t

get corroded. It can be classified as

Coating of less active metal: Less active metals also known

as noble metals protect the base metal from corrosion due to their inactivity.

The protection by less active metal is satisfactory as long as the coating is

perfect. A break or crack in coating may facilitate the formation of electrolytic

cells due to which, more active base metal undergoes corrosion rapidly.

Coating of more active metal: Coating of more active metals like zinc, aluminium, cadmium

protect the base metal from corrosion. In this case, base metal act as a

cathode and coating metal becomes an anode. Thus, the two metals being in

contact with the surrounding medium form a galvanic cell in which cathode

remains un-attacked, while the anode corrodes.

Methods of applying metal coating

The protective metallic coating can be made by the following

different methods

·

Hot dipping: Galvanizing and Tinning

·

Metal spraying

·

Electroplating

·

Metal cladding

·

Diffusion coating: Colorizing,

Chromizing and Sherardizing

Hot dipping

Hot dipping method is based on the process of dipping the base

metal in a molten coating metal covered by a molten flux layer. The flux cleans

the surface of base metal and prevents the oxidation of molten coating metal.

The base metal is of higher melting point like iron, steel, etc and the coating

metal is lower melting point then base metal. Hot dipping is generally done by

two methods

Galvanising

Galvanizing, or galvanization, is a manufacturing process where a

coating of zinc is applied to steel or iron to offer protection and prevent

rusting. In this method, steel or iron is dipped in a molten pool of zinc that

maintains a temperature of around 860°F (460 °C). This molten bath begins a

metallurgical bond between the zinc and the receiving metal. After the metal is

pulled from the bath, it reacts to being exposed to the atmosphere, and the

pure zinc mixes with oxygen to form zinc oxide. The zinc-oxide further reacts

to carbon dioxide and forms zinc carbonate, which makes up the final protective

coating on the material.

Steps involved in hot dip galvanizing

·

The iron or steel article to be

galvanized is first cleaned with dilute sulphuric acid to remove oxide layer

and impurities.

·

It is then dipped in a bath of zinc

ammonium chloride solution and then allowed to dry.

·

The sheet is then dipped molten

zinc.

·

It is then passed under a roller to

make the coating uniform and remove excess of molten zinc.

·

It is then heated at a temperature

of 600o C to 700o C and then cooled down slowly.

Advantages

·

Low installation and maintenance

cost

·

Long endurance

Disadvantages

·

Galvanized coating makes containers

unusable for edible stuffs.

Tinning

Tinning is the process of coating iron with molten tin, which can

be used for edible applications. Tinning is the process of making tinplate,

which consists of sheets of iron or steel that have been thinly coated with tin

by being dipped in a molten bath of that metal. Hence the process is more

precisely described as hot-dipped tin plating. This is done in order to prevent

the iron from rusting.

Steps involved in process of tinning

·

The iron or steel article to be

galvanized is first cleaned with dilute sulphuric acid to remove oxide layer

and impurities.

·

It is then dipped in a bath of zinc

ammonium chloride solution and then allowed to dry.

·

The sheet is then dipped molten tin.

·

It is then dipped in a suitable

vegetable oil, to protect the hot tin coated surface against oxidation.

·

It is then passed under a roller to

make the coating uniform and remove excess of molten tin.

Difference between galvanization and tinning

|

Galvanizing

|

Tinning

|

|

Process of coating steel with a thin coat of TIN to prevent it

from corrosion

|

Process of covering iron or steel with a thin coat of ZINC to

prevent it from rusting.

|

|

Tin protects the base metal iron, from corrosion due to its

noble nature and higher corrosion resistance.

|

Zinc protects iron sacrificially. Since it is more

electro-positive than iron and does not permit iron to pass into the

solution.

|

|

Tin protects underlying iron till the coat is intact. Any break

in coating causes rapid corrosion of iron.

|

In galvanized articles zinc continues to protect the underlying

iron by galvanic cell action even if the coating of zinc is broken at any

place

|

|

Tin coated containers and utensils can be used for storing any

food stuff as tin is non-toxic and protects metal from corrosion.

|

Galvanized containers cannot be used for storing acidic

foodstuffs as zinc reacts with food acid forming poisonous compounds.

|

|

Ideal temperature is around 250 degree C.

|

Ideal temperature is around 450 degree C.

|

|

Zinc chloride is used as flux.

|

Ammonium chloride is used as flux.

|

Metal spraying

Metal spraying, or metallizing, is the process of coating a

surface with metal or alloy using spray equipment. It is used to guard metals

from corrosion, employing zinc or aluminium as basic spray materials. The

typical hard-facing materials used in metal spraying include cobalt, nickel

with a little amount of chromium, and manganese chrome.

Steps involved in metal spraying

·

The spraying gun consists of a duct

for compressed air. The coating metal which needs to be sprayed is fed into the

gun in form of wire.

·

The metal wire gets melted using

compressed air to form a fine spray.

·

The spray can be directed to the

surface where fine molten droplets rapidly solidify and form the coating. This

coating protects the base metal from corrosion.

Advantages

Spraying can be applied to non-metal as well.

Uneven surfaces can be easily protected using metal spraying.

Disadvantages

The process is not so effective as the coating may be porous and

less adherent.

Electroplating

Electroplating is basically the process of plating a metal onto

the other by hydrolysis mostly to prevent corrosion of metal or for decorative

purposes.

Steps involved in electroplating

·

The surface which needs to be coated

is first cleaned and suspended into the electrolyte and made as cathode. The

anode consists of the pure metal whose coating is desired on the article.

·

The electrolyte generally consists

of a salt solution of the coating metal.

·

When electric current is passed

through the solution, the metal ions from electrolyte get deposited on the

article. The equivalent amount of anode gets dissolved in the form of ions and

passed into the electrolyte.

·

A thin layer of superior coating

metal is obtained on the cathode.

Advantages

·

Improves wear resistance.

·

Improves the thickness of the metal

surface.

·

Enhancing the electrical

conductivity like plating a copper layer on an electrical component.

·

Minimizing Friction.

Sherardizing

Sherardizing is a zinc diffusion coating process, which uses zinc

vapor to form zinc alloys with the base material. For sherardizing it is

necessary to have the source (Zn powder) close to the coating surface, because

of the low partial pressure of zinc.

Steps involved in Sherardizing

·

The iron articles to be coated are

first cleaned.

·

The articles are then packed with

zinc dust and zinc powder oxide in a steel drum.

·

The steel drum is provided with

electrical heating arrangement to raise the temperature. The steel drum is

rotated by means of a motor.

·

During this period, zinc gets

diffused into iron forming Fe-Zn alloy at the surface which protects the iron

surface from corrosion.

Advantages

·

The coating of metal is uniform

·

No change in dimension of articles.

Metal Cladding

Metal cladding is a type of protective coating, where the

protective material such as metal powder or foil is bonded to a substrate by

applying heat and/or pressure.

Steps involved in metal cladding

·

The base metal to be protected is

sandwiched between two sheets of coating metal.

·

This cladded metal is then passed

through two heavy rollers maintained at high temperature.

·

The sandwiched metal becomes

cathodic with respect to base metal so that the electrolytic protection is

provided. All corrosion resistance metal can be used as a cladding material.

Advantages

·

It increases the strength of the

base metal.

·

The cladding metal also provide

electrolytic protection to base metal.

Disadvantages

·

Only plain surfaces can be protected

using metal cladding.

·

Base metal cannot be completely

prevented from corrosion using metal cladding.

Paints

Paints are mechanical dispersion mixture of one or more pigments

in a non-volatile film forming material (usually a thinner). Paints are used

for decorative purpose as well as protective coating over metal. Paint needs

time to dry out. To accelerate the drying, small amount of dryers are also

added to the paint.

Characteristics of a good paint

Fluidity: Paint should be

fluid enough so that it easily spreads over the entire surface to be protected.

Coverage: Paints should have

good covering capability.

Durability: A good paint should be durable and long lasting

Adherence: A good paint should adhere to the surface to which it has been

applied.

Appearance: The paint film should look glossy and shinny.

Flexibility: The paint

should not get cracked on drying

Constituents of paints

Paints is a composition of various materials. But some

constituents are essential for a paint. They are discussed below:

·

Binder

·

Pigment

·

Filler/ Extender

·

Volatile organic compound (Thinner)

·

Driers

·

Additives (Anti skinning agents,

Anti settling agent, Plasticizers, fire retardants etc

Binder

Binders are usually resins or oils but can be inorganic compounds.

Binder is the actual film forming component & absolutely required

ingredient of any paint. It consists of a resin and a solvent thinner. It is

the part which solidifies to form the dry paint film when the solvent

evaporates. They are non-volatile & mainly polymers of various types. Different

resins form dry film on the substrate in different manners.

Function of binder

·

Binds pigment, fillers &

additives together

·

Imparts adhesion & strongly

·

It influences gloss, durability,

flexibility and toughness

Pigments

Pigments are finely ground inorganic or organic powders of higher

refractive index (> 1.5). Higher the RI, more the light is bent &

greater the opacity. Good opacity has good lighting absorbing & /or

scattering properties. The colour of pigment depends on the composition of the

pigment used. For example, White lead and titanium oxide is are white pigments

whereas red lead, ferric oxide, etc are red pigments. Good pigments are opaque,

non toxic and chemically inert.

Function of pigment

·

It provides opacity and colour to

paint ilm.

·

Give strength to the paint film.

·

Provides protection to paint by

reflecting harmful ultraviolet light.

·

Increases weather resistance of

paint film

Extender / Filler

Non-expensive commonly natural inorganic materials added to the paint

in order to increase its volume. Extenders are mainly inorganic substances

& do not provide colour to the paint but added to improve adhesion, ease of

sanding and film strength. As they are cheap in comparison to prime pigments,

they reduce overall cost of the paints.

Function

·

thickens the film

·

Increases volume, paint film

thickness

·

reduces cost of the paint

·

imparts toughness, abrasion

resistance & texture

·

Control consistency

Widely used fillers: Calcium carbonate, Gypsum, Ground silica, Barytes, Slate powder, French

chalk, china clay, asbestos, silica, mica, whiting etc.

Driers

Depending upon the nature of the solvent and film thickness, the

drying process may take as long as several hours. Thicker the film, longer the

drying time. If the drying process is artificially accelerated, there may be

problems with adhesion between the protective film and the metal surface.

Metallic salts of Lead, Manganese, Cobalt, etc. of organic acids are generally

used as drier.

Purpose

·

to accelerate the drying process.

Examples: Lead acetate,

Cobalt octate, Manganese octate, Litharge, Red lead, Lead octate, Manganese

dioxide, Zinc sulphate, etc.

Additives

Additives are small amounts of different chemical substances

improving or modifying the paint properties. Added to a paint in amounts 0.001%

& ≤ 5% & have a profound influence on physical & chemical

properties of the paint.

Function

·

Prevent clustering of pigments

·

Texturizers impart textures to the

coatings.

·

Antifreezers helps to withstand

exposure

·

Pigment stabilizers improve pigment

stability

·

Fire retardant properties

Methods of application of paints

Paint is applied to the surface through several methods. Some of

them are discussed below:

Roller coating: Roller coating method is used when the material to be painted is

in form of flat sheets. Roller is dipped in paint and rolled over the material

which needs to be painted. During the passage, the articles are painted

uniformly.

Brushing: An easy method of

applying paint is brushing. Brush is dipped in paint and then the brush is

applied on the surface. A non-viscous and covering paint is must to apply it on

material. A good brush should have flexible yet rigid bristles. Brush gives a

smooth finish on the surface. Paints who are more viscous are first mixed with

a thinner before getting applied.

Spraying: This method involves the application of paint using spray gun.

Spraying method is very useful for uneven surfaces. The process is quick but

more paint is required as compared to other methods. The spray can be directed

to the surface where fine molten droplets rapidly solidify and form the

coating. In recent advancements, paint is made of negative charge and the

article to be painted is made positive. So, when paint is sprayed, negatively

charged particles of paint is attracted to positively charged articles and

hence less paint is wasted.

Dipping: Dipping is the

simplest method of application of paint. The article to be painted is simply dipped

in paint and then the article is taken out and paint is dried. The major

disadvantage of dipping is that thickness of applied paint is not uniform.

Tumbling: Tumble spray

involves placing components in a specially designed, hexagonal shaped unit. A

controlled spray of atomized coating is then applied to parts as the unit

rotates. The hexagon design of the unit is important as the components are

flipped and rotated more than a simple cylindrical unit could. Once the coating

is applied, parts are loaded in baskets and baked in a batch oven.

Chemical resistant paints

Chemical resistant coatings are designed for metal, concrete

floors & walls, Wood & Fiber to prevent the abrasion from harsh

chemicals including the acids and several other abrasive materials. Chemical

resistant paints protect different surfaces from chemical. The chemical

resistance of a coating will depend on number of criteria such as

·

The type of chemical used and its

concentration

·

The duration for which the article

has been exposed to paint

·

Chemical resistant paints are

required in nuclear facilities, liquid spillages, storage of high temperature

chemicals, where enhanced lubrication is required, etc.

Heat resistant paints

Heat resistant paints are designed to withstand high working

temperature on commercial and industrial metallic surfaces and structures from

heat treatment applications. For example, chimneys of furnaces, incinerators operate

at very high temperature. This type of surface requires a paint which does not

breakdown at high temperatures. Heat resistant paint does not deliver fire

retardant properties but still can be used in industrial applications.

Generally high resistant paints are applied using spraying.

Cellulose Paint

Cellulose paints are highly toxic, flammable and very fast drying.

It is one of the industrial paints. Its raw material consists of the reaction

of cellulose obtained from cotton and wood with alcohol and acids.

Cellulose-based paints are not widely used in construction compared to

synthetic and water-based paints. The reason for this is that the harmful

chemicals it contains and the thinner used in thinning is cellulose-based.

Luminous Paint

Luminous paint or luminescent paint is paint that exhibits

luminescence. In other words, it gives off visible light through fluorescence,

phosphorescence, or radioluminescence. There are three types of luminous

paints: fluorescent paint, phosphorescent paint and radio luminescent paint.

Fluorescent paint

Fluorescent paints 'glow' when exposed to short-wave ultraviolet

(UV) radiation. These UV wavelengths are found in sunlight and many artificial

lights, but the paint requires a special black light to view so these

glowing-paint applications are called 'black-light effects'. Fluorescent paint

is available in a wide range of colours and is used in theatrical lighting and

effects, posters, and as entertainment for children.

Phosphorescent paint

Phosphorescent paint is commonly called

"glow-in-the-dark" paint. It is made from phosphors such as

silver-activated zinc sulphide or doped strontium aluminate, and typically

glows a pale green to greenish-blue color. The mechanism for producing light is

similar to that of fluorescent paint, but the emission of visible light

persists long after it has been exposed to light. Phosphorescent paints have a

sustained glow which lasts for up to 12 hours after exposure to light, fading

over time.

Radio luminescent paint

Radio luminescent paint is a self-luminous paint that consists of

a small amount of a radioactive isotope (radionuclide) mixed with a radio

luminescent phosphor chemical. The radioisotope continually decays, emitting

radiation particles which strike molecules of the phosphor, exciting them to

emit visible light.

Emulsion paint

Emulsion paint is water-based paint, that consists of pigment,

emulsifier, coagulant, and water. It's called emulsion because the pigments are

dispersed in water emulsified with an emulsifying agent. Emulsion paints are

quite popular for their durability, easy-to-use features, and low cost.

Emulsion paint consists of tiny polymer particles within which the pigments are

trapped. The particles are suspended in water, then as the paint dries the

particles fuse together creating a film of paint on the wall. Once this happens

the polymer can’t be resuspended in water, which is why you can’t wash a

water-based emulsion paint back off the wall once it has dried. Emulsion paints

are free from hazard and have no objectionable odour.

Metal Paints

Metal paints are paints which easily adhere to metal surfaces.

Paint coating on metal surfaces is applied on bodies for protection and

decoration. The coating on metal may be of galvanic type or barrier type.

Cement paint

Cement paints are prepared by mixing white cement with colouring

pigments, hydrated lime and fine sand. Cement paints are available in form of

powder of particular colour. The dispersion medium may be water or oil

depending on the purpose of coating. Before applying cement paint, a primer

coat consisting of dilute solution of sodium silicate and zinc sulphate is

necessary. Cement paints have water proofing capacity and give a stable and

decorative film.

Water paints or distempers

Distemper paint is an ancient type of paint made of water, chalk,

and pigment. It is bound with either an animal glue or the adhesive qualities

of casein, a resin that comes from solidified milk. The basic constituent of

Distemper Paint is chalk, lime, and water. Such kind of paint can be applied

directly on cement walls without any other coating on them without using the

primer. They are a cheaper option and they stay good for more than 3 to 4

years.

Varnishes

The Varnish is a transparent, hard, protective finish or film

primarily used in wood finishing and also for other materials. Varnish is a

homogeneous colloidal solution of natural or synthetic resins in oils or

thinners or both. It enhances and gives comfort to the grain of the wood and is

resistant to impact, heat, erosion, water, and alcohol. It can be used as a top

coat over a painted surface.

Characteristics of good varnish

·

It should be dry quickly

·

On drying it should form a hard,

tough and durable film.

·

It should have good weathering

properties, resist abrasion and wear well.

·

It should be able to retain its

colour and shine.

·

It should be uniform and pleasant

looking on drying.

Constituent of varnish

The ingredients of varnish are:

Resins

Solvents

Driers

Resins

Commonly used resins are copal mastic, amber gum and lac. Quantity

of varnish depends much upon the quality of resin used. Copal is considered to

be the best, toughest, hardest and is very durable for external work.

Solvents

These must suit the resins used. Boiled linseed oil is used to

dissolve copal or amber, turpentine oil for common resin or mastic, methylated

spirit for lac. Wood naphtha, because of its offensive smell is not suited for

superior works and is used only for cheap varnish.

Driers

These should be added only in small quantities as an excessive

injures varnish and impairs its durability. Litharge or lead acetate are the

commonly used driers in varnish added to accelerate drying process.

Different kinds of Varnishes:

Based on the different solvents used, varnishes are classified

under the following categories:

Oil Varnish

These are made by dissolving hard resins like amber or copal in

oil. They are slow to dry but are hardest and most durable of all varnishes.

They are suited for being used on exposed surfaces requiring polishing or

frequent cleaning and for superior works.

Turpentine Varnish

These are made from soft resins like mastic, common resin is

dissolved in turpentine oil.

Spirit Varnish

Varnishes in which spirit is used as a solvent is known as

spirited varnish or French Polish. Shellac is dissolved in spirit and the

product is applied in a thin layer. This varnish gives a transparent finish

thus showing the grains of the timber. These however, do not weather well and

as such are used for polishing wood work not exposed to weather.

Water Varnish

They consist of lac dissolved in hot water with borax, ammonia,

potash or soda just enough to dissolve the lac. Varnish so made withstands

washing. It is used for painting wall paper and for delicate work.

Japans

Japans are pigmented varnishes which are added to paint to give it

a good colour and lustre. Japans are generally used to paint bicycles and

electrical devices. Japans are usually of two types: Printer’s Japan and

decorative Japans. Printer’s Japans consists of resin dissolved in drying oil

containing drier and thinner. Printer’s Japans make paint more lusturous.

Decorative Japan is prepared by heating linseed oil and lead oxide. This

results in a solid mass which is known as lead oil. This lead oil is then mixed

with asphaltum and thinner to get decorative Japans.

Enamels

Enamel is a type of paint which is traditionally oil-based,

although variations like water-based or latex-based enamels are readily

available in the market. Enamel gets air-dried hard and used as protective as

well. Enamel is considered best for the materials which are of regular use and

thus enamel helps to protect the wear and tear products or the things that are

subject to remain outside the shelter and faces every type of climatic conditions

for example cars. Thus, enamel is considered best for materials like furniture,

vehicles or any kind of wood or metal.

Constituents of enamel

Pigments: Generally,

titanium dioxide and calcium sulphate is used as pigments for enamels. Pigments

as generally white. But when coloured pigments are used, they are referred to

as Japans.

Vehicles: Vehicles make

enamels of glossy finish. The vehicle of enamel is either oil and resin or only

resin. Vehicles increase the viscosity, gloss and colour of enamel.

Driers: Commonly used

driers are naphthenates or resonates of copper, zinc, etc.

Thinners: Thinners used are

turpentine, acetone, etc.

Lacquers

Lacquer is a type of hard and usually shiny coating or finish

applied to materials such as wood or metal. It is most often made from resin

extracted from trees and waxes. Lacquer is a substance that provides a strong

and shiny finish. The main objective of using lacquer is to provide a highly

shiny and glossy coat on the surface of the wood or any object that is being

coated. Lacquer is not a durable substance, and it is only used for its

appearance.

Constituents of liquor

Cellulose derivative: Cellulose derivatives give

durability and water resistance property to the film.

Resins: Resins are used to

provide adhesion, thickness and gloss to film. Resins generally used in

lacquers are copal, alkyd, etc.

Solvents: The solvent is

used to dissolve the film forming material. The solvents used are esters,

ketones, alcohols, etc.

Plasticizers: They reduce

the brittleness of liquor. This improves the adherence and durability of

plasticizers. Commonly used plasticizers are castor oil, chlorinated diphenyls,

etc.

Diluent: Diluents are

generally coal-tar products which reduces the viscosity as well as cost of the

liquor. Benzol and naptha are used as diluents.

Difference between enamel and lacquer

|

Parameters of Comparison

|

Lacquer

|

Enamel

|

|

Definition

|

Lacquer is a coating solution that is

primarily used to give a shiny coating to surfaces

|

Enamel is a hard paint solution that is used

for coloring as well as to give a hard coating on the surface

|

|

Durability

|

Lacquer is not durable and long-lasting

|

Enamel is a durable and long-lasting coating

|

|

Drying time

|

Lacquer dries very quickly, right after

application

|

Enamel takes a longer time to dry

|

|

Thinner

|

Specific lacquer thinners are used

|

Spirits are used as thinner agents while

applying enamel

|

|

Demerit

|

Lacquer develops bubbles if not applied

properly

|

Enamel does not have such bubble formation

|