Water

Water is essential

to life. Without it, the biosphere that exists on the surface of the earth

would not be possible. It is also the only known chemical compound that occurs

in all the three physical states viz., solid (snow, hail, sleet and ice),

liquid (rain, water droplets) and gas (water vapors). Water is the chemical

substance with chemical formula H2O, one molecule of water has two

hydrogen atoms covalently bonded to a single oxygen atom.

Water covers more

than 70 % of the earth’s surface, of which 97% is in the ocean, which is unfit

for human consumption and other uses because of its high salt content. Of the

remaining three percent, 2% is locked in the polar ice caps and glaciers and

only one percent is available as fresh water in rivers, lakes, streams,

reservoirs, and ground water which is suitable for human consumption.

A continuous and supply of clean water is essential for the survival and health

of all living organisms.

Characteristic of

water

Physical

characteristics of water

Turbidity

of water: Turbidity is the amount of

suspended matter in water and expressed in parts per million

Color: The colour of a good water is transparent. The colour of water is

measured by tintometer.

Taste and

odour: Preferably, the water should be free from taste

and odour.

Chemical

characteristics of water

Total

solids and suspended solids: The suspended

solid can be found by filtering the water sample. Total permissible amount of

solids in water is generally limited to 500 ppm.

pH of

water: pH of water should be 7.

Hardness

of water: Hard waters

are undesirable because they may lead to greater soap consumption, scaling of

boilers, causing corrosion and incrustation of pipes, making food tasteless

etc.

Sources of water

Source water refers

to bodies of water (such as rivers, streams, lakes, reservoirs, springs, and

ground water) that provide water to public drinking-water supplies and private

wells. Water on the earth is broadly classified under two categories. They are

Surface water

Ground water

Surface

water

Surface water is

quite a broad term when we look at it. It consists of any above-ground water

which gets collected. For instance, we have ponds, rivers, lakes, oceans and

more. Surface water collects on the ground or in a stream, river, lake,

reservoir, or ocean. Surface water is constantly evaporating out of water

bodies, seeping into ground water supplies, and being replenished by rain and

snow.

Surface water is

the most used source of water. It accounts to at least 80 per cent of the water

used by living beings. Following are the sources of surface water

Rain

water: Rain water is the purest form. It is

obtained by natural process of evaporation and condensation of water.

River

water: A river is a

ribbon-like body of water that flows downhill from the force of gravity. A

river can be wide and deep, or shallow enough for a person to wade across. A

flowing body of water that is smaller than a river is called a stream, creek,

or brook. Some rivers flow year-round, while others flow only during certain

seasons or when there has been a lot of rain. The largest rivers can be

thousands of miles long.

Lake: A lake is a body of water that is surrounded by land. There are

millions of lakes in the world. They are found on every continent and in every

kind of environment—in mountains and deserts, on plains, and near seashores.

Lakes vary greatly in size. Some measure only a few square meters and are small

enough to fit in your backyard. Such small lakes are often referred to as

ponds. Other lakes are so big that they are called seas. The Caspian Sea, in

Europe and Asia, is the world’s largest lake.

Sea water: This is the most impure form of

natural water. Rivers throw all the impurities carried with water into sea. The

continuous evaporation of water from surface of sea increases concentration of

dissolved impurities. This sea water contains about 3.5% of dissolved

impurities, out of which about 2.5% is sodium chloride. Thus, sea water cannot be

used directly for domestic or industrial purpose.

Ground water

When we say

groundwater, we mean the source of water which is found beneath the layer of soil.

It exists in the soil and between rocks and other things. Groundwater

contributes to 30% of water which we use in our daily lives.

A part of rainwater

which reaches earth’s surface or water from river percolates into the earth.

This water travels downwards, during which it comes in contact with various

mineral salts present in the soil and dissolves some of them. Water continues

its downward flow till it meets hard rock.

Spring and well

water is generally clear in appearance as it is filtered through soil layers,

but contains considerable quantity of dissolved salts. The water from well and

spring contains more hardness. The underground water is suitable for domestic

use.

Impurities of

water

Water available on

earth is not in its purest form. The water is generally contaminated with

materials which are often referred to as impurities. The common impurities

present in natural water may be classified as follows:

Suspended particles

Dissolved

impurities

Colloidal

impurities

Biological

impurities

Suspended

impurities: Suspended impurities are the

impurities that are partially soluble in water, and kept suspended in water.

These impurities consist of clay, mud, algae, organic matter, etc. Such

impurities are referred to as suspended impurities. They are present in most of

the surface water. These impurities are generally visible with naked eyes.

Suspended impurities in water if consumed can result in a range of medical

ailments and illnesses.

Dissolved

impurities: The

dissolved impurities include salts and minerals. These minerals are not

important and are harmful to organisms. Dissolved impurities may also include

organic and inorganic salts as well as gases.

Gases: The dissolved gases present in water

may include oxygen, carbon dioxide, nitrogen, etc. These gases are soluble in

natural water.

Mineral

salts: The commonly

observed salts in natural water are carbonate, bicarbonates, magnesium, etc.

When salts of calcium and magnesium are present in water, it becomes hard

water.

Colloidal

impurities: Colloidal

impurities are such impurities which doesn’t settle down even in standing water

and cannot be removed by filtration. Size of colloidal particle is about 10–4 cm to 10–7 cm.

Biological

impurities: Biological

impurities in water are caused by the presence of living organisms. These

include algae, protozoa, pathogens, bacteria, viruses, microbes, and parasites

along with their cysts (eggs) in contaminated water. Such water is dangerous

for human consumption.

Hard and soft

water

Soft water

Soft water is the

type of water that contains lower amounts or lower concentrations of minerals

like calcium and magnesium. However, soft water may include salt like sodium or

potassium dissolved in it. Soft water tastes salty while drinking.

Hard water

The water with

naturally present minerals like magnesium and calcium with detectable amount is

called hard water. Hard water contains more minerals, but that doesn’t mean

it’s contaminated. Contamination is different than mineral content and refers

to germs and bacteria instead. Minerals are valuable nutrients for your body,

although too many may pose health risks. Minerals improve water’s taste.

Difference

between hard water and soft water

|

Hard Water

|

Soft Water

|

|

It is rich in minerals

|

Contains very few elements

|

|

Soap is not so effective

|

Soap is easily effective

|

|

No foam and lather from soaps

|

Bubbly lather from soaps

|

|

Leaves spots on the washed dishes after they are dried

|

Does not leave any spots on dishes after they are dried

|

|

Contains minerals like magnesium and calcium

|

Contains sodium ion

|

|

Sometimes preferred drinking water

|

Sometimes not preferred drinking water

|

|

Example: Groundwater like deep wells

|

Example: Rainwater

|

|

Hair and skin become dry

|

Hair and skin become soft

|

Causes of

hardness of water

Hardness of water

is due to the presence of calcium and bicarbonates present in it. Deposition of

calcium and magnesium salts make the water hard. Water receives such mineral

while moving in its examples. Some reasons are mentioned below:

Rainwater absorbs

carbon dioxide from air and also from decaying plants on soil. This rain water

when flows over the rocks containing calcium and magnesium carbonate reacts

slowly with the substances forming bicarbonates. Chloride and sulphate of

calcium and magnesium are also present on the surface layer. These salts are

soluble in water. Thus, water becomes hard.

Types of

hardness

There are two types

of hardness. They are as follows

·

Temporary or carbonate hardness

·

Permanent aur non carbonate hardness

Temporary

or carbonate hardness

The presence of

magnesium and calcium carbonates in water makes it temporarily hard. In this

case, the hardness in water can be removed by boiling the water.

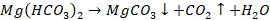

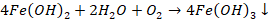

When we boil water

the soluble salts of Mg(HCO3)2 is converted to Mg(OH)2

which is insoluble and hence gets precipitated and is removed. After

filtration, the water we get is soft water.

Permanent

or non-carbonate hardness

Permanent or

non-carbonate hardness is due to the presence of dissolved chlorides, sulphates

of calcium and magnesium. Permanent hardness cannot be destroyed on boiling. It

requires special chemical treatment for the removal of hardness. There are

several softening methods that is used to treat permanent hard water. Some of

them

Difference

between temporary and permanent hardness of water

|

Temporary hardness

|

Permanent hardness

|

|

This type of hardness is due to soluble bicarbonates of calcium

and magnesium.

|

It is due to soluble chloride and sulphate salts of calcium and

magnesium.

|

|

Since it is due to carbonates, and hence it is known as

carbonate hardness.

|

It is due to salts other than carbonates and hence known as non-

carbonate hardness

|

|

Temporary hardness can be removed by boiling.

|

Permanent hardness cannot be removed by boiling. They require

different softening techniques

|

Harmful

Effects of Hard Water

·

Some of the most common signs of hard water include:

·

Linens and clothes look dull and feel rough.

·

Ugly stains on white porcelain and scale build-up on faucets

·

Low water pressure from showers due to clogged pipes.

·

Chalky, white residue or spots appear on dishes.

·

Strains appearing in the shower.

Degree of

hardness

The amount of

hardness causing substances in a certain volume of water measures the degree of

hardness. The hardness of water is always calculated in terms of calcium

carbonate CaCO3. However, it is never responsible for causing hardness

as it is insoluble in water.

The choice of CaCO3

is due to its molecular weight 100 and equivalent weight 50. The

units commonly used to express hardness of water is as follow

Different

units used to express degree of hardness

·

ppm (parts per million) = This is weight in milligrams of CaCO3 equivalent to

all hardness causing substance in one million (106) milligrams of

water.

·

mg/L (milligram per litre) = weight in milligrams of CaCO3 equivalents in on

litre of water.

·

⁰Cl (degree

Clark) = weight in grams

of CaCO3 equivalents in 70,000 grams of water.

·

⁰Fr (degree

French) = weight in

grams of CaCO3 equivalents in 105 grams of water.

Relationship

between these units

1 ppm = 1 mg/L = 0.1⁰Fr = 0.07 ⁰Cl

Boiler and steam

generation

The manufacturing

industries need water for a great variety of purposes out of which steam

generation is the most important one. Hard water has an adverse effect on steam

boilers. Hence, water for raising steam in boilers must be soft and must not contain too much impurities. Impure water produces

foam, and also deals with several other problems such as corrosion, caustic

embrittlement, scale and sludge formation.

A boiler or steam generator is a device used to create steam by

applying heat energy to water. It is a closed vessel made of high-quality steel

in which steam is generated from water by the application of heat. The water

receives heat from the hot gases formed by burning fuel through the heating

surface of the boiler. Steam is mainly required for power generation, process

heating, and space heating purposes.

Problems associated with hard water in boiler

Corrosion: The most common problem associated with boiler due to the use of

hard water is corrosion. Corrosion causes the decaying of boiler. Hard water

consists of dissolved gases and salts which chemically reacts with metallic

surface of boiler. This leads to decaying of boiler.

Caustic embrittlement: Caustic embrittlement is also a type of corrosion for boiler.

This type of corrosion is caused by the use of highly alkaline water in boiler

and it is generally observed in the boiler which operates under a high

pressure. During water softening process, small amount of sodium carbonate is

added. In high pressure boilers, sodium carbonate decomposes to give sodium

hydroxide and carbon dioxide.

Due to the form of sodium hydroxide (caustic soda), water becomes

more alkaline. There are minute cracks in the inner lining of boiler. The

alkaline water flows into the cracks of boiler lining due to capillary action.

Water evaporates and dissolved caustic soda is left behind. The alkaline action

of caustic soda attacks the surrounding areas of cracks thereby dissolving iron

material of the boiler. This causes embrittlement of boiler parts,

particularly, at stressed parts like rivets, bends, joints, etc. causing even a

failure of the boiler.

Prevention for caustic embrittlement

·

Use sodium phosphate instead of

sodium carbonate for softening water.

·

Use lignin as additives to the

boiler water which will block the minute cracks thereby preventing infiltration

of caustic soda solution.

·

By adjusting the alkalinity of water

to optimum level.

Priming and Foaming: When a boiler is steaming

(i.e., producing steam) rapidly, some particles of the liquid water are carried

along-with the steam. This process of 'wet steam' formation is called priming. Priming

is caused by

·

the presence of a large amount of

dissolved solids

·

high steam velocities,

·

sudden boiling

·

improper boiler design

·

sudden increase in steam-production

rate.

Foaming is the production of persistent foam or bubbles in

boilers, which do not break easily. Foaming is due to presence of substances

like oils (which greatly reduce the surface tension of water).

Priming can be avoided by:

(i) fitting mechanical steam purifiers;

(ii) avoiding rapid changing steaming rate;

(iii) maintaining low water levels in boilers

(iv) efficient softening and filtration of the boiler-feed water.

Foaming can be avoided by:

(i) adding anti-foaming chemicals like castor oil

(ii) removing oil from boiler water by adding compounds like

sodium aluminates.

Limitation of priming and foaming

(i) dissolved salts in boiler water are carried by the wet steam

to super-heater and turbine blades, where they get deposited as water

evaporates. This deposit reduces their efficiency

(ii) dissolved salts may enter the parts of other machinery, where

steam is being used, thereby decreasing the life of the machinery;

(iii) actual height of the water column cannot be judged properly,

thereby making the maintenance of the boiler pressure becomes difficult.

Scale and sludge formation

In a boiler, water is continuously evaporated and converted into

steam. As a result, the water becomes saturated due to increase in the

concentration of dissolved impurities. Finally, a stage is reached where the

ionic products of these salts exceed their solubility product and are thrown

out as precipitates on the inner walls of the boiler.

Sludge: It is soft, loose

and slimy precipitate formed within the boiler. It is formed at comparatively

colder portions of the boiler and are collected at the bends. It is formed by

substances which have greater solubility in hot water than in cold water, e.g.,

MgCO3, MgCl2, CaCl2, MgSO4, etc

Disadvantages of sludge formation

·

Sludges are poor conductors of heat,

so they tend to waste a portion of heat generated.

·

Excessive sludge formation disturbs

the working of the boiler.

Sludge can be removed by using

1) Softened water

2) by blow down operation i.e., drawing off a portion of the

concentrated water.

Scales: It is hard

deposits firmly sticking to the inner walls of the boiler. The hardness of

scale depends upon the nature of impurities present in the water. The most

troublesome scales are formed due to the presence of sulphates and silicates of

calcium and magnesium. Such scales are non-porous and non-conductor of heat.

Scales are difficult to remove, even with the help of hammer & Chisel.

Scale is formed due to:

i) Decomposition of Calcium bicarbonate:

In high pressure boilers, CaCO3 is soluble due to

formation of Ca (OH)2

ii) Deposition of CaSO4

Solubility of CaSO4 decreases with increase in temperature.

It is completely insoluble in super-heated water.

Hard scale formation takes place in high pressure boilers

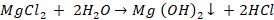

iii) Hydrolysis of Magnesium salts:

Soft scale formation due to hydrolysis of Mg salts in high

pressure boiler.

Disadvantages of scale formation:

i) Wastage of fuel:

Rate of heat transfer is greatly reduced due to poor conductivity

of scales

Overheating is required for steady supply of heat hence fuel

consumption increases.

ii) Lowering of boiler safety:

To supply steady heat overheating is required, which makes the

boiler material weak &soft. Results in distortion of boiler tube &

makes the boiler unsafe to bear the high pressure.

iii) Decrease in efficiency of boiler:

Deposition of scales in valves and condensers choke them

partially& decreases the efficiency of boiler

iv) Danger of Explosion:

Due to uneven expansion the thick scales get cracked, results in

formation of large steam & develops high pressure. It may cause explosion

of boiler.

Removal of scales:

·

Mechanical/chemical method

·

Loosely adhering scales are removed

with the help Scraper/wire brush

·

Brittle scales are removed by giving

Thermal shocks

·

Loosely adhering scales are removed

by frequent blow down operation (frequently removing precipitates)

Softening methods of water

The process of removing soluble calcium and magnesium salts from

hard water is called softening the water. During the process of softening of

hard water, the soluble salts are converted into insoluble salts. These

insoluble salts then can be filtered and soft water can be obtained. Several

methods are used for the softening of water. Some of them are as follows:

·

Boiling

·

Lime-soda process

·

Zeolite or permutit process

·

Ion exchange process

·

Clark’s method

Boiling

Boiling water only removes temporary hardness. Boiling water is

certainly one of the most effective ways to soften it. The boiling will have

the effect of draining the hard water minerals to the bottom, like calcium and

magnesium. Boiling precipitates the dissolved minerals out of the water. Since

boiling removes the water’s calcium content, the result is softer water.

When you boil water, the salts precipitate leaving clean, soft

water.

Put some water in a pot and leave it boiling for at least five

minutes for the best results. After the water has boiled sufficiently, turn the

heat off.

Let the water cool. Allow sufficient time, so the mineral deposits

sink to the bottom. Next, pour the soft water from the pot and leave the

mineral deposits in the pot.

Boiling is a quick and cheap way to fix hard water for consumption

purposes. However, it only addresses temporary hardness and not permanent

hardness.

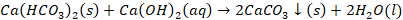

Clark’s method

Clark’s method is one of the solutions for treating hard water by

adding slaked lime into the water. Hardness of water can be defined as the

dissolved content of divalent metal cations in water. In Clark’s method, hard

water is treated with Ca (OH)2. This method removes hardness by

conversion of bicarbonates into carbonates.

Clark's technique for softening water:

Hard water is softened with in Clark's water softening technique

(slaked lime). Clark's reagent is Calcium Hydroxide. Calcium hydroxide is used

in Clarke's method to soften water (lime). It eliminates transient hardness. By

turning bicarbonates into carbonate, it softens the water.

Slaked lime, either in solid or liquid form, is added to water

using this technique. Soluble bicarbonates are changed into insoluble

carbonates as a result.

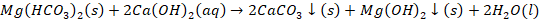

In this method, a calculated amount of lime is added to hard

water, it precipitates out calcium carbonate and magnesium hydroxide which can

be filtered off.

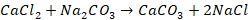

Chemical reaction involved in Clark’s method

Lime soda method

The water is treated with lime or a combination of lime and soda

ash (carbonate ion). These chemicals react with the hardness and natural

alkalinity in the water to form insoluble compounds. The compounds precipitate

and are removed from the water by sedimentation and, usually, filtration. When

water has minimal magnesium hardness, only calcium needs to be removed. Only

enough lime and soda ash are added to water to raise pH to between 10.3 and

10.6, and calcium hardness will be removed from the water.

When lime and soda ash are added, hardness-causing minerals form

nearly insoluble precipitates. Calcium hardness is precipitated as calcium

carbonate CaCO3. Magnesium hardness is precipitated as magnesium

hydroxide Mg (OH)2. These precipitates are then removed by

conventional processes of coagulation/flocculation, sedimentation, and

filtration.

Chemical reaction involved in soda ash method

|

Hardness

|

Lime

|

Precipitate

|

|

+ +

|

|

|

|

+ +

|

|

|

|

+ +

|

|

|

|

+ +

|

|

|

Soda ash method

Soda Ash is the common name for sodium carbonate, which is a

chemical compound with the formula Na2CO3. This compound

is also known as washing soda and soda crystals. In this method water is

treated with a calculated amount of soda ash (also referred to as washing

soda). Soda ash converts the chlorides and sulphates of calcium and magnesium

into their respective carbonates which get precipitated.

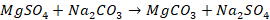

Chemical reaction involved in soda ash method

Zeolite or permutit process

The zeolite softening process is used for removing both the

temporary and permanent hardness of the water by precipitating the calcium and

magnesium present in water as insoluble zeolites.

In this process of softening of water, there is an exchange of Ca2+

and Mg2+ ion with the help of zeolite. Hence it is called the

zeolite softening process. Zeolite is micro porous mineral which is used as

catalyst in many industrial purposes such as water purification. The zeolites

are hydrated aluminosilicates and general composition is Na2Al2Si2O8.

Zeolites are of two types i.e., synthetic and artificial. The natural zeolite

that is used for water softening is gluconites. Permutit is the synthetic

zeolite that is most used in water softening. Permutit are more porous, glassy

and have higher softening capacity than gluconites.

Zeolite process is commercially accepted for the fact that zeolite

can be easily regenerated. When Ca2+ and Mg2+ ions

containing hard water passes through a bed of sodium zeolite, the sodium ions

are replaced by the calcium and magnesium ions. When all sodium ions are

replaced by calcium and magnesium ions, the zeolite becomes inactive. Then

zeolites need to be regenerated. Brine solutions are passing through the bed of

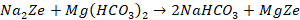

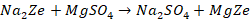

inactivated zeolite. The following reactions takes place to form Na2Ze.

The chemical reactions that take place during softening process

are as follows:

Ion exchange method for water softening

Aside from industry, ion-exchange softeners are widely used in

small water systems and individual homes. Ion-exchange resins, exchanges one ion

from the treated water for another ion in the resin (sodium is one component of

softening salt, with chlorine being the other). Sodium is exchanged for calcium

and magnesium by ion exchange resin. Certain organic compounds possess a

property like zeolite i.e., they are capable of exchanging ions. Such organic synthetic compounds are known as resins. There

are two types of resins

Cation exchange resins: These resins are capable of exchanging

rapidly cations by H+ ions. Cation exchange resins can be

represented as RH2, so their exchange reaction with cations is

Anion exchange resins: These resins are capable of exchanging

rapidly anions by OH– ions. Anion exchange resins can be

represented as

If hard water is passed first

through cation exchanger and then through anion exchanger, the resulting water

will be free from both cations and anions and water is said to be deionised or

demineralised.

The process of ion exchange is

carried out as follows:

It consists of two cylindrical towers, out of which the first

tower consists of cation exchanger (RH2) and the other one consists

of anion exchanger[R’(OH)2]. Hard water is first allowed to pass

through a tower containing cation exchanger, which removes all the cations like

Ca++, Mg++, Na++ and releases H+ ions

Thus, the anions like chlorides, sulphates and bicarbonates are

converted into their corresponding acids HCl, H2SO4 and H2CO3.

In other words. This acidic water is then passed through another tower

containing an ion exchanger, where acids are converted into water.

Consequently, the water thus produced is free from all ions and is virtually

distilled water. The water is finally freed from dissolved gases like CO2

by passing it through a degasifier, which is a tower whose sides are connected

to vacuum pump. High temperature and low pressure reduce the quantity of

dissolved CO2 and O2 in water.

Difference between ion-exchange process and zeolite process

|

Ion-exchange process

|

Zeolite process

|

|

This process can produce softened water with residual hardness

ranging between 0 to 2 ppm.

|

This process can produce softened water with residual hardness

ranging between 0 to 15 ppm.

|

|

The resultant water is suitable for all types of boilers,

especially high pressure boilers.

|

The resultant water is not suitable for use in high pressure

boilers. Water can be used only in low or medium pressure boilers.

|

|

Capital cost is higher

|

Capital cost is less

|

|

It occupies more space

|

It occupies less space.

|

|

This process is useful for acidic as well as alkaline water.

|

This process is not useful for highly acidic water.

|

Plumbo solvency

All drinking water is plumbosolvent, which means it can dissolve

very small amounts of metals if they come into contact with them. Plumbo

solvency refers to the dissolution of lead in water. It increases lead

concentration in water that passes through lead pipes. This makes water unfit

for human consumption and may lead to health hazards. Lead is toxic. It affects

the functioning of heart, kidneys, reproductive and nervous system.

Water plumbosolvency can be counteracted by reaching a pH of 7.5

by increasing the pH with lime or sodium hydroxide (lye) or by providing

protection on the inside of lead pipes by applying phosphate to water treatment

works.

While the optimal pH for plumbosolvency prevention is 7.5,

performance in the range pH 7.2-7.6 is still very good. Attaining this pH has

been shown to decrease blood lead concentrations in the population.

Additionally, chlorinating water eliminates dissolved lead. With

this purpose, if the water could have been in contact with lead, water to be

used for drinking or cooking food can never be drawn from a hot-water tank.

Water should be taken from a cold water tap and heated in a saucepan or kettle

without lead or lead solder.

Water treatment methods

Following methods are generally carried out to make water fit for

drinking

·

Sedimentation

·

Coagulation

·

Filtration

·

Sterilization

Sedimentation

Sedimentation is the process of removing suspended impurities by

allowing the water to stay undisturbed for some period of time in large tanks

when most of the suspended particles settle down due to the force of gravity.

The clear water is then taken out from the tank with the help of pumps.

Coagulation

Coagulation is the chemical water treatment process used to remove

solids from water, by manipulating electrostatic charges of particles suspended

in water. This process introduces small, highly charged molecules into water to

destabilize the charges on particles, colloids, or oily materials in

suspension. Selecting the right coagulant for a system will enhance overall

system performance, and particularly improve solids removal efficiency by

enhancing filter and clarifier performance. The commonly used coagulants are

the salts of iron and aluminium. These coagulates react with bicarbonates

present in water and form bulky gelatinous precipitate called flock. These

flocks absorb or catch suspended fine particles from water and form bigger

flocks, which settle down quickly. The addition of coagulants to water also

removes colour, odour and improves its taste.

Filtration

Filtration is a process of removing insoluble colloidal and

bacterial impurities by passing water through a bed of proper sized material.

During filtration, the clear water passes through filters that have different

pore sizes and are made of different materials (such as sand, gravel, and

charcoal). These filters remove dissolved particles and germs, such as dust,

chemicals, parasites, bacteria, and viruses. Activated carbon filters also

remove any bad odours.

Water treatment plants can use a process called ultrafiltration in

addition to or instead of traditional filtration. During ultrafiltration, the

water goes through a filter membrane with very small pores. This filter only

lets through water and other small molecules (such as salts and tiny, charged

molecules).

Sterilization

Sterilisation (also referred to as disinfection in other sources)

is the final process to make potable water. It is where all microorganisms are

killed or removed. The process of destroying these disease-causing bacteria and

microorganisms etc from water is known as disinfection or sterilization of

water. The chemicals used for sterilization are known as sterilizers. The

disinfection of water can be carried out by any of the following methods

·

Boiling

·

Chlorination

·

Ozonisation

·

Aeration

·

Ultra-violet rays

Boiling: This is the simplest

method of sterilization. More often, sterilization is the boiling of water

before domestic use. Boiling kill all the pathogenic bacteria like cholera and

typhoid within five minutes. But this method is useful only for household

purposes, because this process is quite expensive for industrial processes.

Chlorination: The

chlorination can be carried by either of the following (i) By using chlorine

gas (ii) By adding bleaching powder (iii)

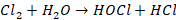

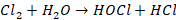

By using chlorine gas Cl2

Chlorination is the process of adding chlorine to drinking water

to kill parasites, bacteria, and viruses. Different processes can be used to

achieve safe levels of chlorine in drinking water. Using or drinking water with

small amounts of chlorine does not cause harmful health effects and provides

protection against waterborne disease outbreaks. It reacts with water to form

hypochlorous acid and nascent oxygen; both are germicides.

However, excess of chlorine should be avoided because it produces

unpleasant odour, taste and irritating effect on mucous membrane. The treated

water should not contain more than 0.1-0.2 ppm of free chlorine.

By adding bleaching powder (CaOCl2)

Bleaching powder is a good sterilizer for small water works. Bleaching

powder which is chemically called as calcium oxychloride (CaOCl2) is

an active agent which is used to kill germs and bacteria in drinking water. The

main content of the bleaching powder is the Chlorine element which acts as the

main disinfectant material.

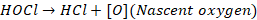

Bleaching powder when exposed to moisture will release chlorine and

this chlorine kills off the germs and disinfects the area. If this is added to

water, the chlorine released will react with water and will cause production of

oxygen in the atomic state which is highly reactive.

Disadvantages of using bleaching powder

Disadvantages of using bleaching powder

·

Bleaching powder introduce calcium

in water thereby making it more hard.

·

If used in an excess amount, it

imparts a bad taste and disagreeable smell to water.

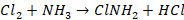

By using chloramine (ClNH2)

Chloramination is the process of adding chloramine to drinking

water to disinfect it and kill germs. It is sometimes used as an alternative to

chlorination. Chloramines are a group of chemical compounds that contain

chlorine and ammonia. The particular type of chloramine used in drinking water

disinfection is called monochloramine which is mixed into water at levels that

kill germs but are still safe to drink. Chlorine and ammonia are mixed in ratio

2:1 by volume to produce a compound known as chloramine.

Ozonisation

This is an effective method of sterilization of water. Ozone O3

is unstable and it decomposes into molecular oxygen O2 and nascent

oxygen O

The nascent oxygen thus produced is very effective for killing all

the germs and bacteria. In ozonisation, water is allowed to percolate through a

tower having perforated partition. Ozone is allowed to enter from the bottom

which kills the germs when they come in contact with water. Sterilized water is

collected at the bottom of the tank. This method is quite expensive and hence

not commercially accepted.

Aeration

Aeration treatment consists of passing large amounts of air

through water and then venting the air outside. The air causes the dissolved

gases or volatile compounds to release from the water. The air and the

contaminants released from the water are vented. This is the most modern method

of purifying water for town supply. Water is forced under pressure through a

perforated pipe. As water sprays into air, it comes in contacts with the oxygen

of air and it is exposed to the ultra-violet rays of the sun. This kills the

bacteria and the oxygen oxidises organic matter present in the water. It

removes colour and odour also. Natural aeration takes place in streams and

rivers when the water flows slowly in its bed or when it falls from a certain

height.

Ultra violet rays

The invisible ultra violet rays are very effective in killing all

types of bacteria. This method is widely used for disinfection of swimming pool

water, because it does not require any chemical to be mixed with water. This

method requires focussing of uv rays of water which makes this method quite

expensive. Hence this method is not employed for municipal water supply.