Metals and Alloys

Metallurgy

Metallurgy is defined as a

process that is used for the extraction of metals in their pure form. It is a

process of extraction of metals from their ores economically and profitably.

Metals are commercially extracted from minerals at low cost and minimum effort.

Metallurgy deals with the process of purification of metals and the formation

of alloys.

Minerals

Minerals are substances

naturally formed in the earth. A mineral is a naturally occurring inorganic

substance with a definite chemical composition and ordered atomic structure. Minerals

are native forms in which metals exist. Metals are commercially extracted from

minerals at low cost and minimum effort. Minerals are broadly classified as

Primary

minerals: Minerals which were formed by igneous process

that is from the cooling down of the molten materials called magma are referred

to as primary minerals. For example, quartz, mica, etc.

Secondary

minerals: Secondary minerals are

formed with the help of primary minerals. Primary minerals are altered to form

secondary mineral. For example: mica is altered to form illite.

Ores

The metal ores are found in the

earth’s crust in varying abundance. The extraction of metals from ores is what

allows us to use the minerals in the ground. Ores are very different from the

finished metals that we see in buildings and bridges. An ore is a naturally

occurring deposit of geologic material (rock) that includes a sufficient

quantity of one or more valuable elements or compounds that it can be extracted

for economic gain. These valuable elements include metals like copper,

platinum, iron, lead, gold, silver, aluminum, nickel, and many more. Ores may

also contain nonmetals like silicon or diamond. These valuable substances can

be extracted and used in a variety of ways, from use in jewelry making to the

manufacturing of electronic devices. Ores vary widely depending on the chemical

composition of the parent rock, as well as the natural process by which they

were formed.

Difference between Ores and Minerals

Here we

have provided the major differences between Minerals and Ores.

|

Minerals

|

Ores

|

|

All the naturally occurring substances that are present in the

earth’s crust are known as Minerals.

|

Ores are usually used to extract metals economically. A large

number of ores are present.

|

|

All Minerals are not ores.

|

All ores are minerals.

|

|

Minerals are native forms in which metals exist.

|

Ores are mineral deposits.

|

Some ores and minerals

|

Iron

|

Haematite

Magnetite

Siderite

Iron pyrites

|

Fe2O3

Fe3O4

FeCO3

FeS2

|

|

Copper

|

Copper

pyrites

Malachite

Cuprite

Copper glance

|

CuFeS2

CuCO3.Cu(OH)2

Cu2O

Cu2S

|

|

Zinc

|

Zinc

blend/Sphalerite

Calamine

Zincite

|

ZnS

ZnCO3

ZnO

|

Gangue: Gangue

are impurities associated with minerals and ores. These impurities are removed

to extract metals

Flux: A

substance which is added to the charge in the furnace to remove the gangue

(impurities) is known as flux. Flux is a substance introduced in the smelting

of ores to promote fluidity and to remove objectionable impurities in the form

of slag. Limestone is commonly used for this purpose in smelting iron ores.

Other materials used as fluxes are silica, dolomite, lime, borax, and fluorite.

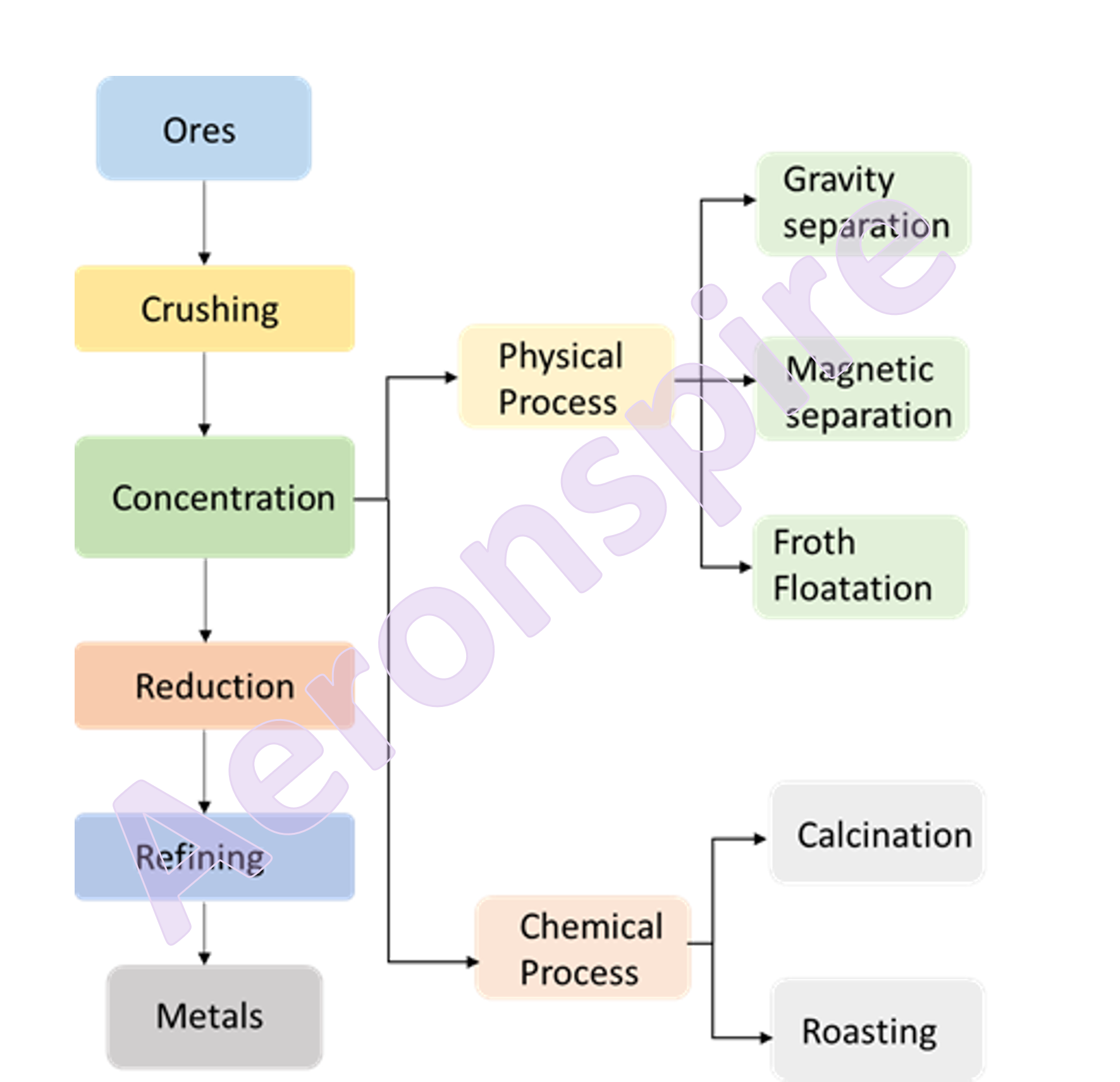

Steps involved in

metallurgical process

Generally following operations

are performed on ores to extract metals

Step 1: Crushing

Step 2: Concentration

Step 3: Reduction

Step 4: Refining

Crushing

The

ores occur in nature as huge lumps. These lumps are unsuitable for further

steps. They are broken to small pieces with the help of crushers or grinders.

These pieces are then reduced to fine powder with the help of a ball mill or

stamp mill. This process is called pulverisation. The amount of

crushing depends on the size of lumps. Different method of crushing is used for

different size of lumps.

Concentration

The

ores are usually found mixed up with large amounts of non-metallic impurities

such as, sand, mica, limestone, felspar, earthy and rocky impurities. These

unwanted impurities are called gangue or matrix and have to be removed before

extracting the metals. The process of removal of unwanted impurities

(gangue) from the ore is called ore concentration or ore dressing or ore

benefaction. The powdered ore is concentrated by one of the physical or

chemical process. The physical process involves gravity separation, magnetic

separation and froth floatation process. Chemical method involves calcination

and roasting.

Physical Process

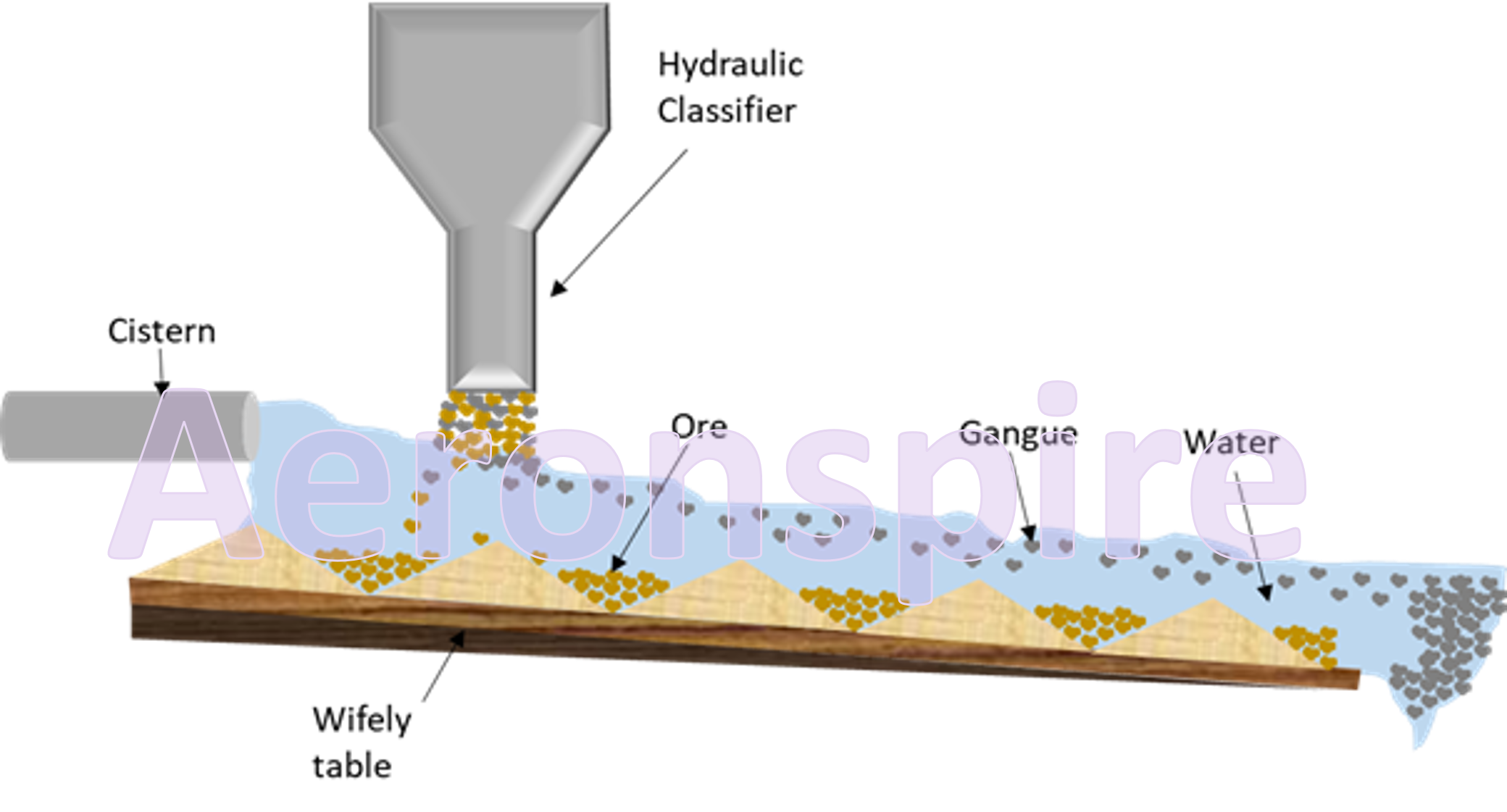

Gravity separation

This

method is based on the differences in the specific gravities of metallic ores

and the gangue particles. Therefore, this method is known as gravity

separation. This method is frequently used when the ore particles are heavier

than the earthy or rocky gangue particles. In this method, the fine ore

collected after crushing is placed on a slopy surface (wifely table especially

designed for gravity separation method) and washed with a running stream of

water. The lighter impurities (gangue) are washed away, while the heavier ore

particles sink at the bottom of sloping platform. Generally, oxide ores like

haematite (Fe2O3) or tinstone (SnO2)

are concentrated by gravity separation method.

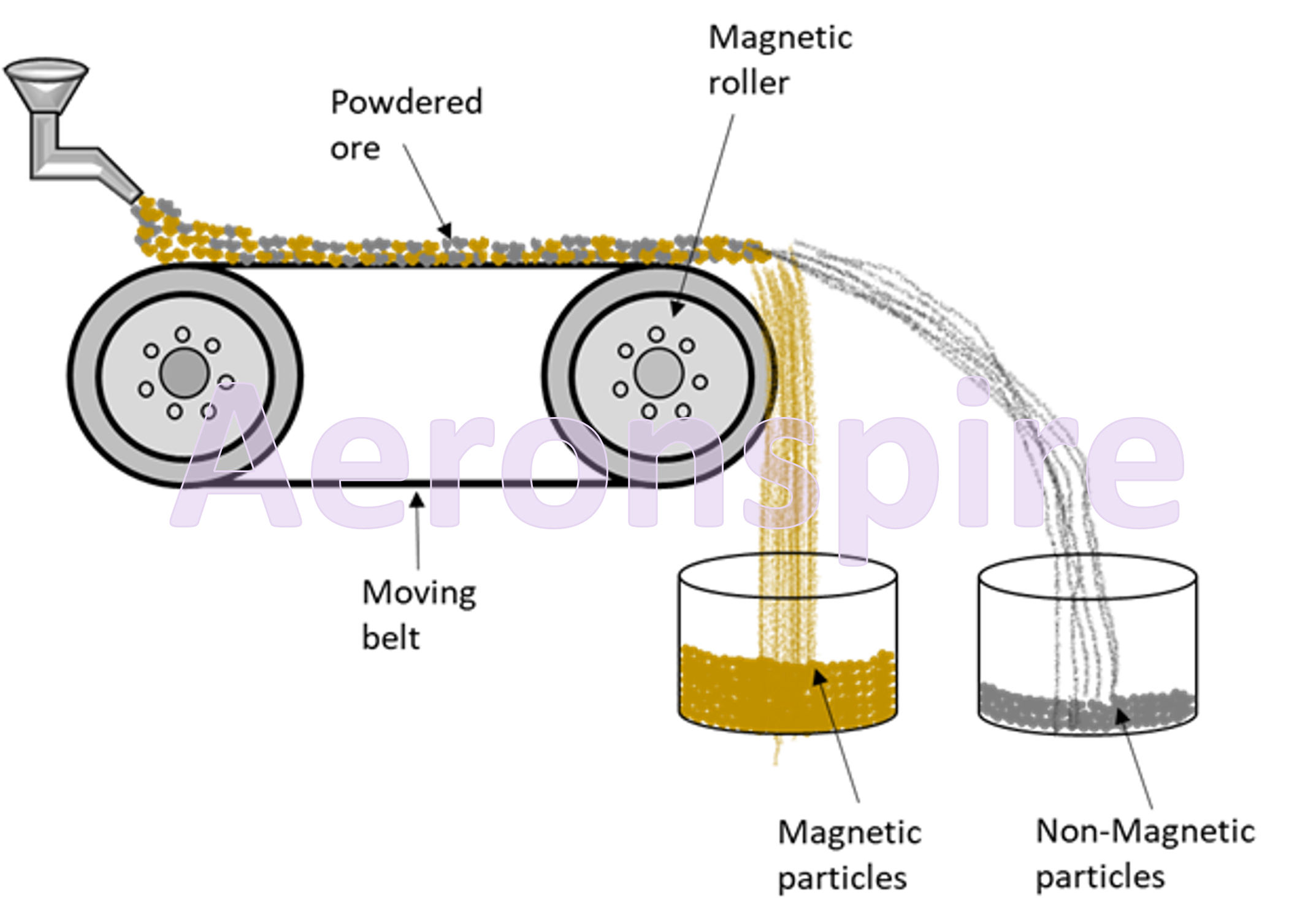

Electromagnetic separation

This

method is used for concentration of magnetic particles from non-magnetic

particles. This method is widely used for the separation of two minerals, when

one of them happens to be magnetic. The magnetic mineral can be separated from

the non-magnetic one by this method. For example, mixture of FeWO4

(magnetic) and cassiterite SnO2 (non-magnetic) are separated by this

method. The powdered ore is made to fall through a leather conveyor belt. The

conveyor belt is placed on a magnetic roll. The leather belt of conveyor moves

through electromagnetic roller. The magnetic impurities fall from the belt near

the roller due to its electromagnetic property while the non-magnetic

impurities fall far away from the roller.

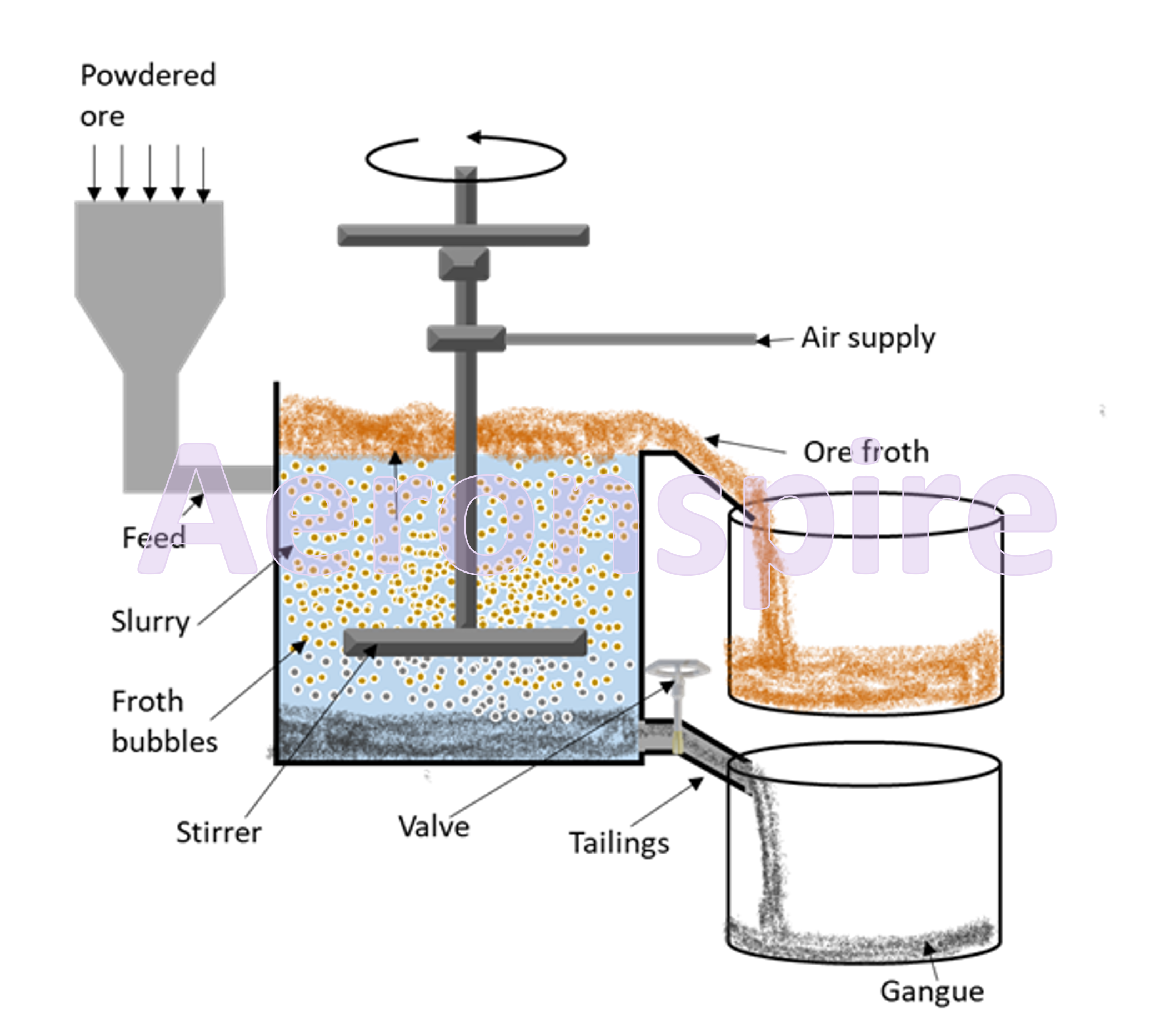

Froth Floatation Process

This

method is extensively employed for the preliminary treatment of the minerals

especially sulphides. The process is based on the difference in wetting

characteristics of the gangue and the ore with water and oil. The ore is

preferentially wetted by the oil and the gangue particles by water. Particle

sized ore particles are mixed with water. The mixture obtained is called

slurry. A collector which acts as a surfactant (a substance which tends to

reduce the surface tension of a liquid in which it is dissolved) chemical

(usually mixture of water and pine oil) is added to the slurry, this is done to

enhance the hydrophobic nature of the mineral. The slurry has now been converted

into pulp. This pulp is added to the container filled with water and then air

jets are forced into it to create bubbles. The required mineral is repelled by

water and thus gets attached to the air bubbles. As these air bubbles rise up

to the surface with mineral particles sticking to them, these are called froth.

This Froth is separated and further taken for the next process of refining and

extraction.

Advantages

ü Almost

all types of minerals can be separated by this process.

ü Surface

properties can be controlled and altered by the flotation reagent.

Disadvantage

ü Result

can vary due to slime

ü Highly

expensive and complex

Chemical Process

Calcination

Metals

are usually obtained from oxide ores after going through the electrolysis or

reduction process. While oxide ores are easy to reduce, it is not the same with

carbonates and sulphides. These ores are turned to metals only after converting

sulphides and carbonates to an oxide ore. Calcination is the process of heating

ore strongly in the absence of air to a temperature insufficient to melt it.

The ore is heated below the melting

point either in limited supply or absence of air. Thus, calcination is mostly

used in the decomposition of limestone (calcium carbonate) to carbon dioxide

and lime (calcium oxide). Calcination is done in hearth of reverberatory

furnace (a furnace in which ores are heated by flames of a fuel) when the doors

are kept closed. The main purpose of calcination are:

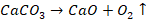

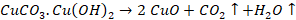

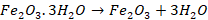

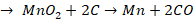

ü

To remove carbonate

and hydroxide ore into oxide

Limestone:

Malachite:

Haematite:

ü To

remove the moisture

ü To

remove the volatile impurities

ü To

make the mass porous, so that it can be easily reduced to the metallic state.

Roasting

Roasting

is a process of metallurgy where the ore is converted into its oxide by heating

it in the presence of excess air above its melting point. While calcination is

the process mostly used in the oxidation of carbonates, roasting is a method

that can be used for converting the sulphide ores. Roasting is done in the

hearth of a reverberatory furnace when the doors are kept open for the free

supply of air. This process is generally used in case of sulphide ores.

The

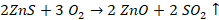

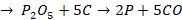

main purpose of roasting are:

ü To

convert sulphide into oxide and sulphate

ü To

remove the moisture

ü To

remove volatile impurities like sulphur, arsenic, antimony and phosphorus in

the form of their oxides.

ü To

oxidise easily oxidisable substances

Difference between calcination and roasting

|

Calcination

|

Roasting

|

|

It

is the process of heating the ore to a high temperature in the absence of

air, or where air does not take part in the reaction.

|

The

process of heating the concentrated ore in the presence of air to a high

temperature so as not to melt is called roasting.

|

|

Usually

carbonate ores or ores containing water are calcined

|

Usually,

sulphide ores are roasted

|

|

Organic

matter, if present in the ore, gets expelled and the ore becomes porous.

|

The

impurities of P, As and S are removed as their oxides which being volatile,

escapes as gases.

|

|

It

is done in reverberatory furnace. The holes of furnace are kept closed.

|

It

is also done in reverberatory furnace but the holes of the furnace are kept

open to allow the entry of air into the furnace.

|

Reduction

The

oxide of the metal obtained as a result of Calcination or roasting is converted

into a free state by reduction. Reduction of metal oxide means removal of

oxygen to refine the metal to its free state. This is done with the help of

reducing agents such as Carbon (C), Carbon Monoxide (CO), Hydrogen (H2),

etc. Reduction can also be carried out by using electricity. Depending on the

type used, it can be classified in three processes i.e.

(a) Smelting

(b) Aluminothermic process

(c) Electrolysis

(a) Smelting

It is

the process of heating the ore or mineral above its melting point. In this

process, calcined ore is mixed with coke and flux like CaO and this mixture is

strongly heated above its melting point. The coke converts the ore into molten

metal while the gangue is removed in the form of slag. Smelting can be carried

out in blast furnace. It is also carried out in reverberatory furnace

sometimes. The flux added to remove the gangue from ore can be acidic or basic

in nature.

The hot

blast of dry air is blown into the furnace just above the hearth through a

number of pipes called twyers. In the well of the furnace there are two outlets

known as tap holes. Furnace charge is comprised of ore, coke, flux, etc. The

upper tap hole is used to remove slag and the lower one is used to remove the

molten metal. To remove the gangue in ore, certain oxides are added to the ore

while melting. These oxides are referred to as flux. If impurity is basic,

acidic flux is used and is impurities are acidic then flux used is basic. The

flux and gangue are converted to some fusible mass known as slag. This slag is

a fusible chemical compound formed by the combination of the added flux and

gangue present in ore.

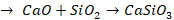

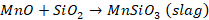

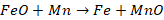

For

example, in extraction of copper

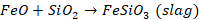

So FeO

is impurity and it is basic in nature. Now, to remove this impurity, we will

use acidic flux like SiO2. This flux and impurity will react to form

slag.

Similarly,

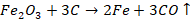

in extraction of iron, we have haematite ore

The

impurity is SiO2 which is acidic, so flux will be basic. Therefore,

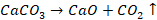

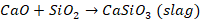

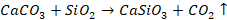

limestone (CaCO3) will be used as flux. It decomposes at high

temperature to give lime. This lime reacts with silica to form slag.

This

can be written as

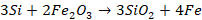

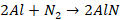

(b) Aluminothermic process

If the

oxides of a metal are very stable, aluminium is used as a reducing agent in

place of carbon at high temperature. Aluminothermic is a process of extracting

metals by reduction of a metal oxide to form metal using aluminium powder, the

aluminium acts as a reducing agent. It is an exothermic reaction which liberates

a large amount of heat. Practically, this method can be used to reduce all the

metallic oxides, with oxide of magnesium being the only exception.

Here

are few examples of Alumino-thermite process:

Reduction

of ferrous oxide to ferrous metal

Iron

(III) oxide is mixed with aluminium powder and is ignited with a burning

magnesium ribbon. Aluminium reduces iron oxide to produce molten iron metal

with the evolution of heat. The chemical reaction is gives as:

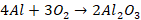

Cr2O3

is reduced to chromium metal

A

mixture of Chromic oxide and powdered aluminium in ratio of 3:1 and is ignited

by a piece of magnesium ribbon. A large amount of heat is liberated during this

process and chromic oxide is reduced to chromium. The chemical reaction is

gives as:

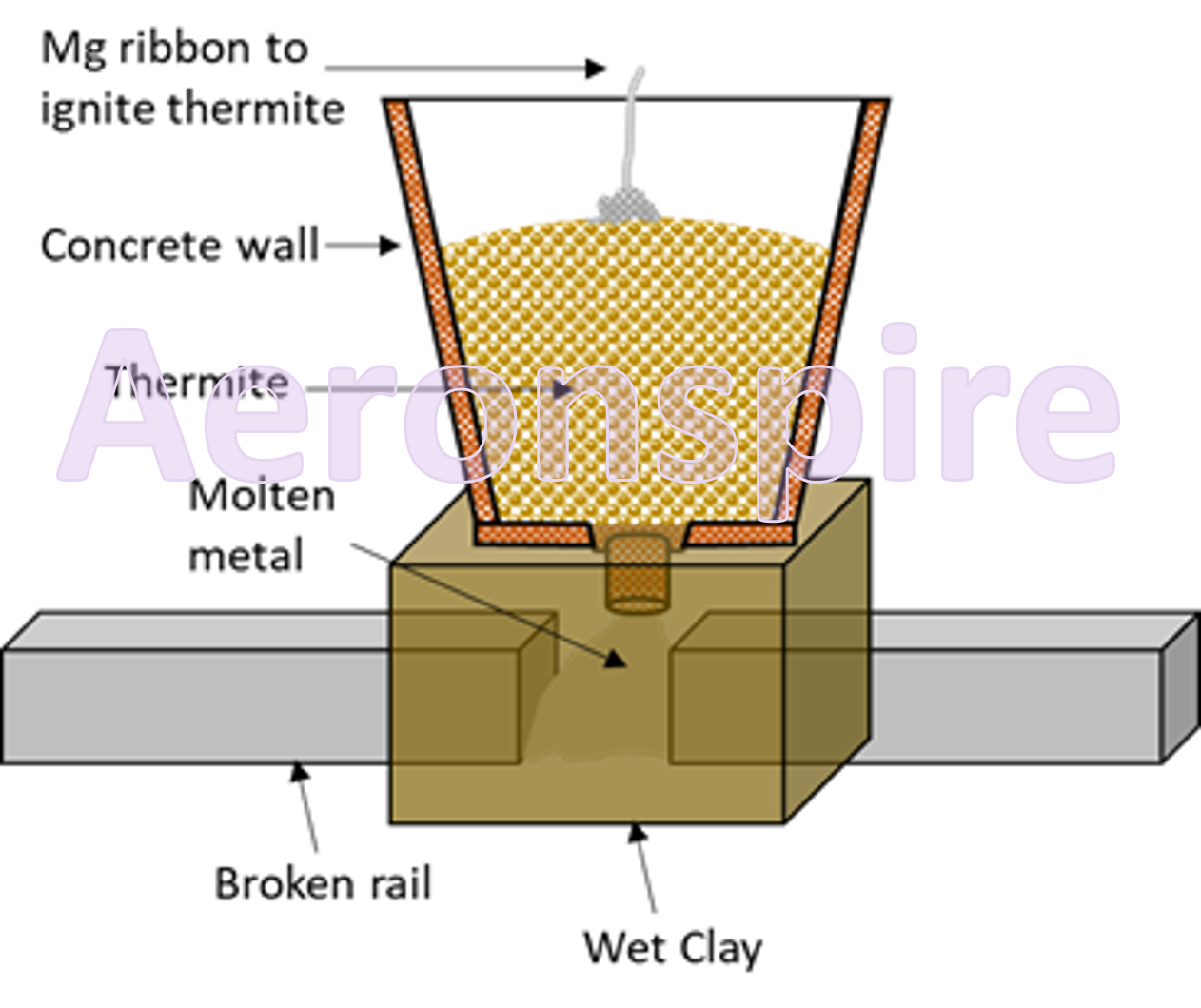

A

mixture of aluminium powder and metallic oxide in ratio 1:3 parts by weight are

known as thermite. Aluminium at high temperature has a great affinity for

oxygen. The reaction is exothermic; hence it liberates large amount of heat.

Metals obtained by this method are highly pure.

This

method is also used to weld the broken rails. The ends of the broken rails are

surrounded with a clay mould. A mixture of iron (III) and aluminium powder

(thermite) is ignited by magnesium ribbon in funnel above. The molten iron thus

obtained runs into the mould. This produces a perfect union upon cooling.

(c) Electrolysis

Electrolysis

is nothing but reduction of metal with the help of electricity. This method is

used to extract metal from oxides of very active metals. These metals form

strong bonds with oxygen, chlorine, etc. so that they are not reducible by

carbon.

These

metals cannot be obtained from their aqueous solution. If aqueous solution is

used, then H+ ions is discharged at cathode. This ion may will gain electron

and form H2 gas. The metals can only be obtained if we brought them

in their molten form. Suppose we want to extract Sodium from sodium chloride

(NaCl).

Two

electrodes are dipped in molten NaCl. These electrodes are then connected to

battery. The electrodes dipped are inert in nature. Now, the electrode

connected to negative terminal of battery will attract the Na+ ions.

Now Na+ will gain electrons and form solid sodium. Thus, we can say

that reduction takes place at cathode. Now, the electrode connected to positive

terminal of battery will attract the Cl– ions. These ions will lose

electrons at anode. Thus, we can say that, oxidation takes place at anode.

At

cathode, we have

At

anode, we have

Refining

The

metal obtained from electrolysis is in pure form. So, it does not require

refining. But metals obtained from all the other processes apart from

electrolysis contains small amount of other elements. The process of

purification of metal to get extra pure metal is referred to as refining. There

are several methods to refine a metal. Some of them are as follows:

ü

Poling

ü

Liquation

ü

Distillation

ü

Electrolytic refining

Poling

Poling

is a method that includes a green log of wood to purify a metal. It is

typically used to purify metals like copper or tin that are in the impure form

of a copper oxide or tin oxide. A log of wood which is still green is used to

stir the liquid metal. The hydrocarbons in the green wood can reduce the metal.

The molten metal is placed in a concrete container. This hot crude molten metal

is stirred with green logs of wood. Also, during stirring, large quantities of

air is absorbed by the molten metal and such absorbed air oxidises the

oxidisable impurities. The oxidised impurities escape either as vapour or form

scum over molten metals. The scum thus formed is then removed by perforated

ladle.

Liquation

Liquation

is another method for refining of metal. This method is particularly suitable

for metal whose melting point is comparatively lower. The melting point of the

impurities is higher than the metal. The metals are converted into liquid

state by supplying heat at a temperature slightly above their melting point.

The crude metal is placed on a slopy surface. The metal with lower melting

point melts first and falls down the slope in a container. The impurities are

not melted and stays on slope. The impurities left behind are known as slope.

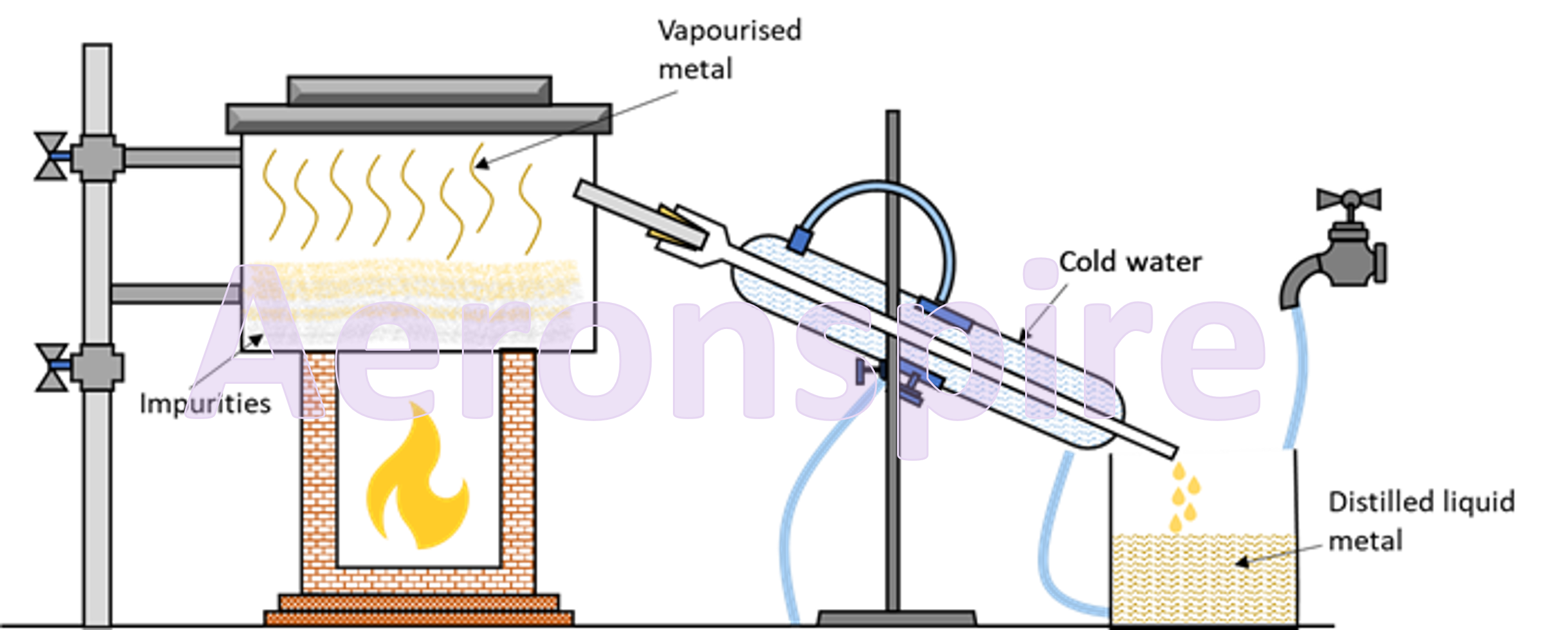

Distillation

This

method is used for the purification of metals which possess a low boiling point

such as mercury and zinc. In this process, the impure metal is heated above its

boiling point so that it can form vapours. The impurities do not vaporise and

hence they are separated. The vapours of the pure metal are then condensed

leaving the impurities behind.

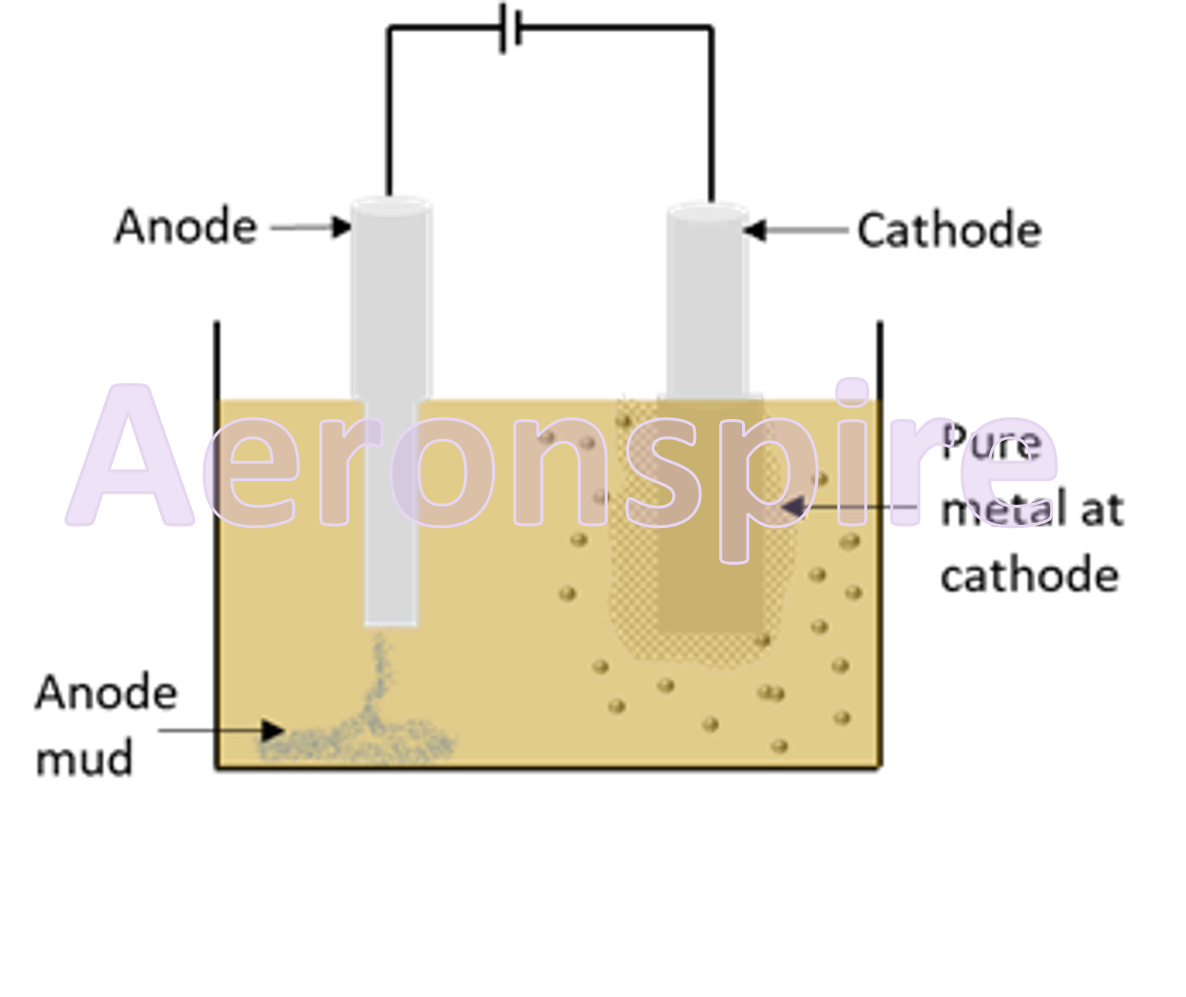

Electrolytic refining

Electrolytic

refining is a process of refining a metal (mainly copper) by the process of

electrolysis. As far as the mechanism of the process is concerned, during

electrolysis, a large chunk or slab of impure metal is used as the anode with a

thin strip of pure metal at the cathode. In this setup, an electrolyte (metal

salt aqueous solution) depending on the metal is often used.

The

clean or pure metal is formed at the cathode when the electrical current of a

sufficient voltage is applied by dissolving impure metal at the anode. When an

electric current with a definite voltage is passed through the bath, anode goes

on dissolving and only the pure metal is deposited on the cathode which grows

in size. Electrolytic refining is also sometimes referred to as

Electrorefining. Metals which are less electropositive than the one being refined

settle below the anode and is known as anode mud.

Metallurgy of Iron

Iron is

most widely used metal. It has occupied its space in our day to day lives like

buildings, ships, aeroplanes, etc. It is the 4th most abundant

element on earth after oxygen, silicon and aluminium. It is found in combined

state in nature such as oxide, sulphate, silicates, etc. Iron is also present

in our blood and it is very important for our body as well. It is found in

combined state in soil, rocks, etc.

The

important minerals of iron ore are as follows:

Oxides

Magnetite: Magnetite

is a very common iron oxide (Fe3O4 or FeO.FeO3)

mineral that is found in igneous, metamorphic, and sedimentary rocks. It is the

most commonly mined ore of iron. It is also the mineral with the highest iron

content (72.4%). It is magnetic and black in colour. It is also known as

Ferrosoferric oxide. This gives high quality of iron and mostly found in USA,

Sweden, Canada and India.

Haematite: Haematite

Fe2O3 is heavy and relatively hard oxide mineral. It is

red in colour. It is an important iron ore because of its high iron content

(70 percent) and its abundance. It is mostly found in USA, Brazil, China and

India.

Limonite: Limonite, one of the major

iron minerals, hydrated ferric oxide Fe2O3.nH2O.

It is brown in colour. The limonite ore was the lowest in grade of all the

oxides, with an iron content of 40%-60% percent. It is found in Belgium,

Germany, France and India.

Carbonate

Siderite

is a mineral composed of iron(II) carbonate (FeCO3). It is also

known as ferrous carbonate. It constitutes 40-45% of iron. It occurs in England

and West Bengal.

Sulphides

It is

found in form of iron pyrites FeS2, Copper pyrites CuFeS2,

Arsenical Pyrites FeAsS. The presence of sulphur in ore makes iron hard and

brittle and thus useless for many processes. But the sulphide ore is also rich

in copper, nickel, etc. So, this ore is not recommended for extraction of iron

but can be used to extract other metals.

Iron is

produced in three different commercial forms depending upon the number of

impurities present, especially carbon. They are:

Pig

iron: Iron obtained from reduction using carbon and

lime as reducing agent is basically pig iron or cast iron. In more general

term, an alloy containing more than 2% of carbon (other impurities are also

present) is called as pig iron. Pig iron is direct metallic product obtained

from blast furnace. It cannot be shaped into articles by forging or hammering.

It is therefore, melted and casted using moulds of desire shape. It is

therefore also referred to as cast iron.

Steel: Steel

is made from iron ore, a compound of iron, oxygen and other minerals that

occurs in nature. The raw materials for steelmaking are mined and then

transformed into steel using two different processes: the blast furnace/basic

oxygen furnace route, and the electric arc furnace route. Steel consists of

0.2% to 1.5% Carbon.

Wrought

Iron: Wrought iron is also known as malleable iron

and is very pure form of iron. It does not contain more than 0.5% carbon. It is

useful in application like chain, bolts, nails, etc. Wrought iron is composed

primarily of iron with 1 to 2% of added slag, the by-product of iron ore

smelting.

Extraction of iron

Extraction

of iron is mainly done in two major steps:

Step I: Preliminary

treatment

(a)

crushing and grinding

(b)

concentration

(c)

calcination or roasting

Step II: Smelting

(Reduction)

Preliminary treatment

The

first step in preliminary treatment is crushing and grinding.

(a) Crushing and grinding:

The ore

obtained in natural form is hard large bulky lumps. These lumps are first

broken into smaller pieces using a grinder. They

are broken to small pieces with the help of crushers or grinders. These pieces

are then reduced to fine powder with the help of a ball mill or stamp mill.

This process is called pulverisation.

(b) Concentration:

The

ores are usually found mixed up with large amounts of non-metallic impurities

such as, sand, mica, limestone, felspar, earthy and rocky impurities. These

unwanted impurities are called gangue or matrix and have to be removed before

extracting the metals. The process of removal of unwanted impurities (gangue)

from the ore is called ore concentration or ore dressing or ore benefaction.

The concentration of iron ore is done in two steps. Firstly, the ore is

concentrated using gravity separation method. In this method, the fine ore

collected after crushing is placed on a slopy surface (wifely table especially

designed for gravity separation method) and washed with a running stream of

water. The lighter impurities (gangue) are washed away, while the heavier ore

particles sink at the bottom of sloping platform. The mass then received free

from clay, sand and other earthy impurities are then dried and subjected to

magnetic separation. The conveyor belt is placed on a magnetic roll. The

leather belt of conveyor moves through electromagnetic roller. The magnetic

impurities fall from the belt near the roller due to its electromagnetic

property while the non-magnetic impurities fall far away from the roller. This

concentrates the ore upto 90% to 95%.

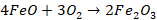

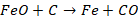

(c) Roasting:

The

oxidised metal is brought to its free method by roasting. The concentrated ore

is calcined or roasted in a reverberatory furnace at a low temperature, with a

little coke. Roastings brings following change to the ore:

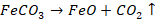

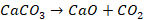

Carbonate

ore is converted to oxide:

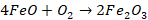

Ferrous

oxide is oxidized to ferric oxide and thus its conversion to ferrous silicate

(slag) is avoided

The

mass is dried up by removing moisture

The

lighter non-metallic impurities such as sulphur, arsenic, phosphorus etc. are

all removed as volatile substances.

Ore

becomes porous and hence easy to reduce.

Reduction

The ore

is then reduced to highly concentrated iron.

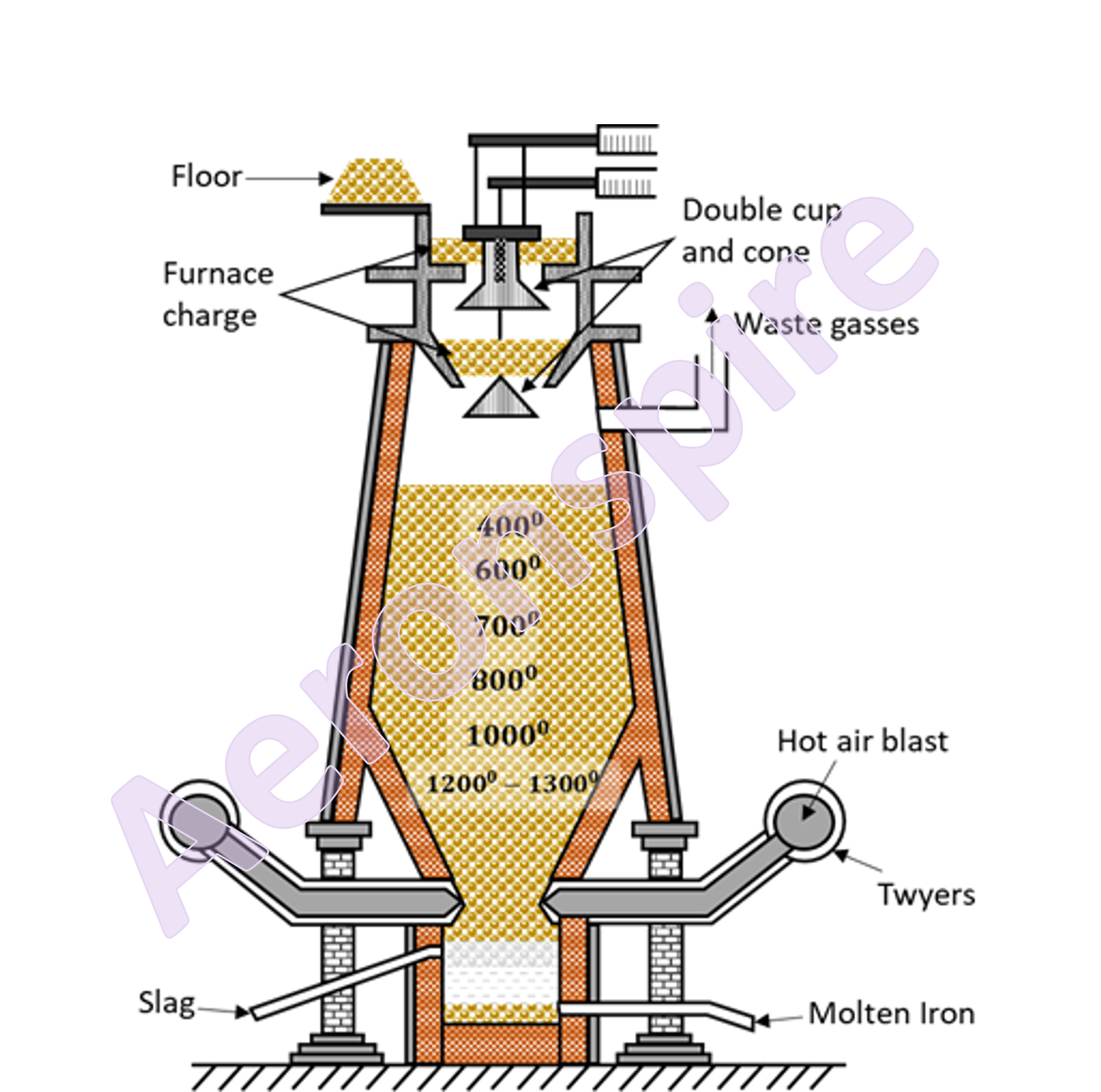

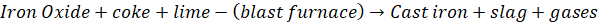

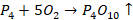

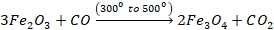

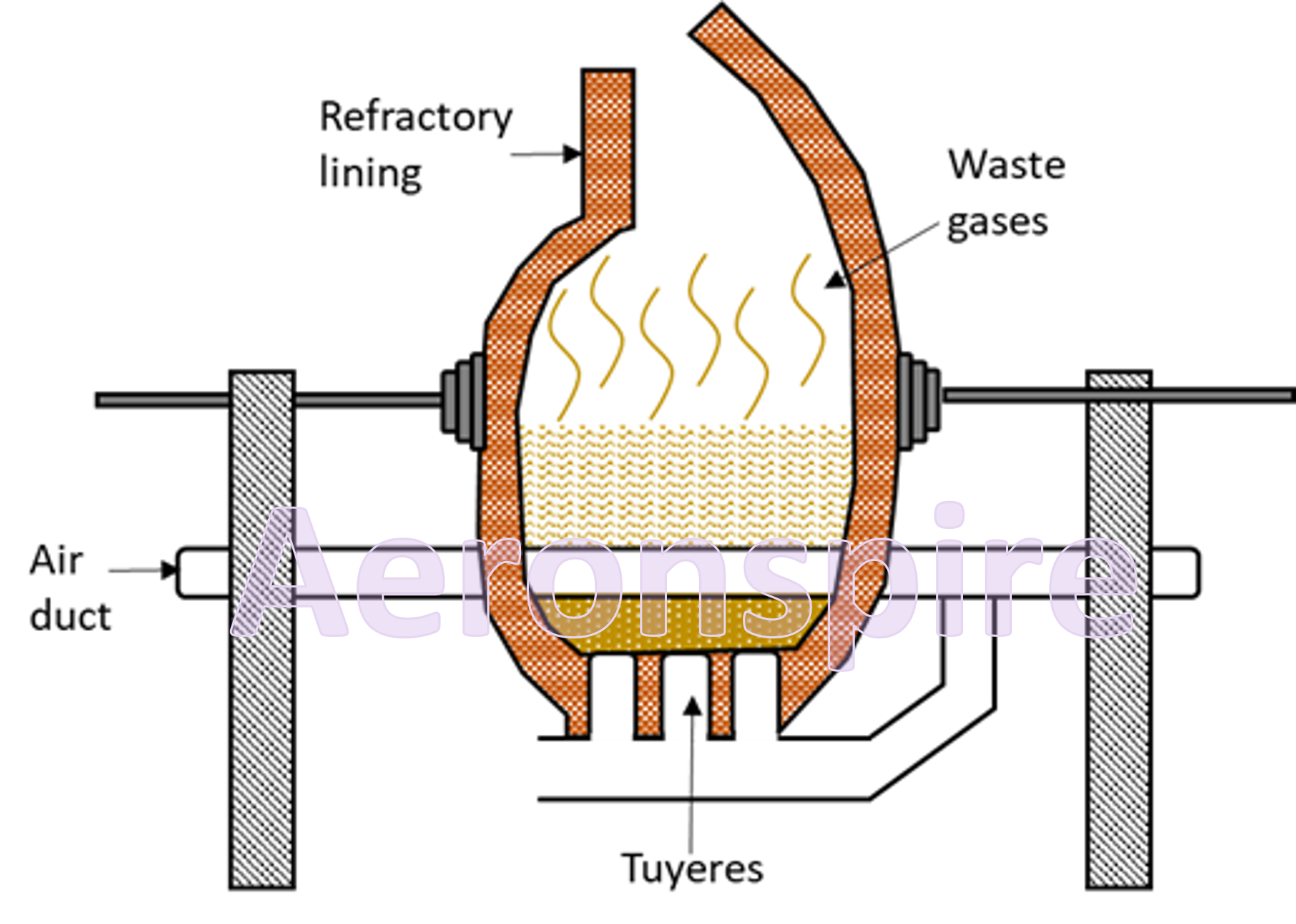

Smelting

The

process of reduction of iron ore to iron is done in blast process. The process

is known as smelting. The purpose of a Blast Furnace is to reduce the

concentrated ore chemically to its liquid metal state. A blast furnace is a

gigantic, steel stack lined with refractory brick where the concentrated iron

ore, coke, and limestone are dumped from the top, and a blast of hot air is

blown into the bottom. At the top, it is provided with double cup and cone

structure to permit charging without escape of waste gases. The upper part of

the furnace is called

the

throat, the middle part is known as body and the bottom part is referred to as

hearth. The region between body and hearth is bosh. The diameter of furnace

increases upto bosh. From the bosh downwards, the diameter decreases upto

twyers. A little above the base, the furnace is provided with series of water

jacketed pipes called twyers.

Working

The

charge is provided through double cup and cone mechanism. The charge

constitutes of calcined ore, de-sulphurised coke and limestone in ratio of

8:4:1. Various reactions takes place in blast furnace at different

temperatures. The reactions occur at different temperatures from 250o

C near throat to 1500o C near hearth. From throat to bosh, the

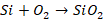

reaction takes place in three different zones as shown below:

(i)

Zone of reduction (300o C - 800o C)

(ii)

Zone of heat absorption (800o C - 1200o C)

(iii)

Zone of fusion (1200o C - 1500o C)

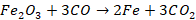

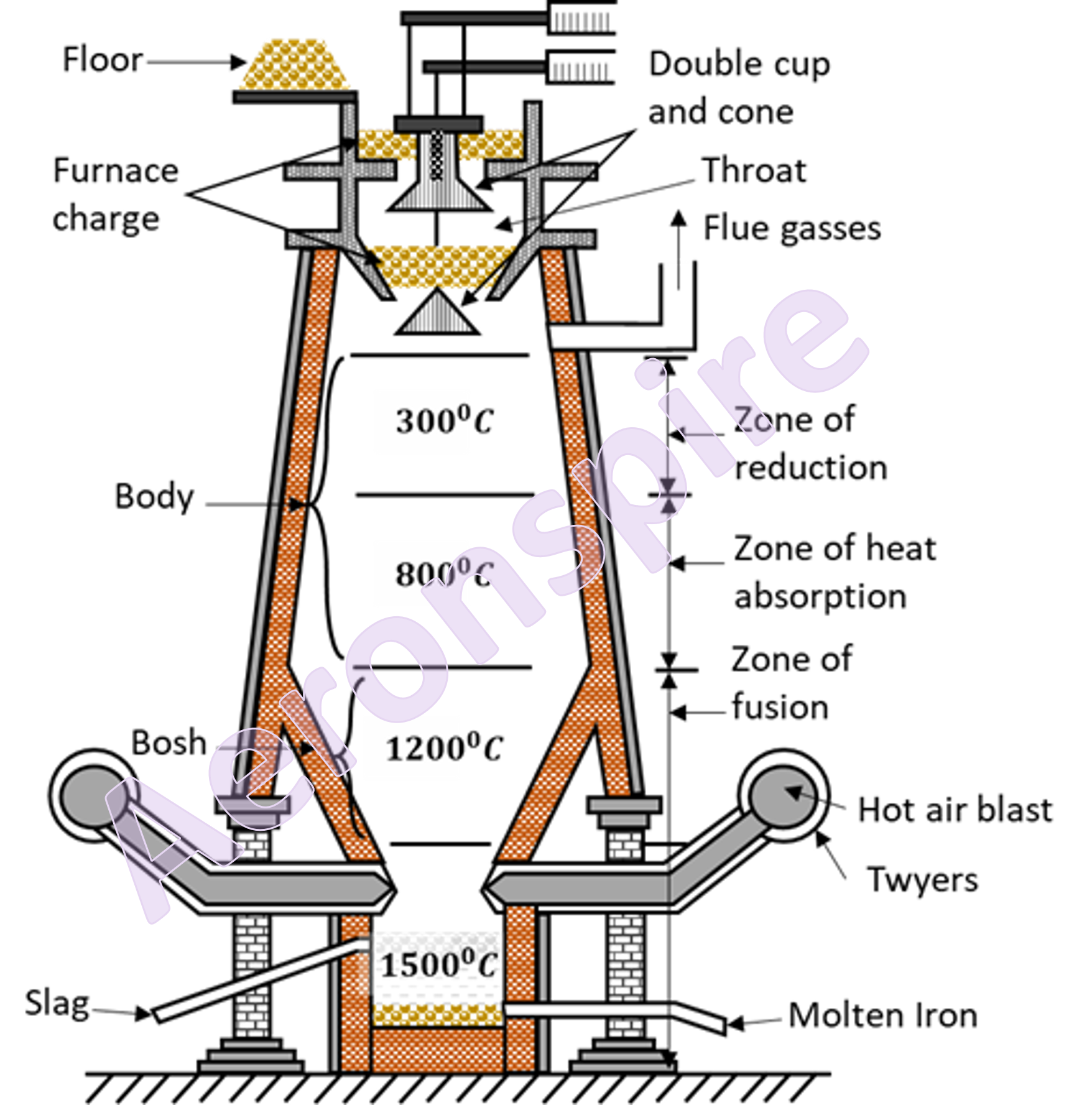

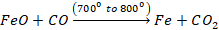

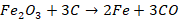

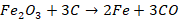

Zone of reduction (300o C - 800o C)

The

main reaction that occurs near the top of the furnace is reduction of the iron

oxide to metallic iron by carbon monoxide.

The

process of reduction continues as charge flows down the furnace. Series of

reaction takes place at different stages.

At the

same time, the limestone present in the charge is also decomposed to produce

lime

The

metal produced at first is spongy. Therefore, simultaneously with the process

of reduction, a part of metallic iron reacts with carbon monoxide to form

ferric oxide.

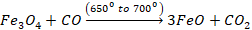

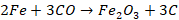

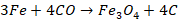

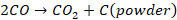

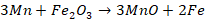

Zone of absorption (800o C - 1200o C)

In this

region, unreacted iron oxides get reduced to iron by red hot coke

Carbon

monoxide gets disproportionate to CO2 and carbon powder

Lime

obtained at the end of first zone combine with impurities to produce slag

Other

impurities get reduced to the elementary substances and are mixed with finished

iron

Zone of fusion (1200o C - 1500o C)

The

temperature of the bottom region is 1500o C. Iron melts in this

region. Molten iron gets collected through the bottom outlet. Slag also melts

at lower temperature and since it is lighter than iron, it floats over molten

iron and gets removed through another outlet. The molten iron is then sent into

sand moulds and cast into pigs or led to steel furnace and converted into

different type of steels. The output from blast furnace is cast iron or pig

iron whose composition is given below:

|

Iron

|

92%

to 95%

|

Phosphorus

|

0.5%

to 1%

|

|

Carbon

|

2.5%

to 4.5%

|

Manganese

|

0.2%

to 1%

|

|

Silicon

|

0.7%

to 3%

|

Sulphur

|

0.1%

to 0.3%

|

This

pig iron can then be converted to steel or wrought iron as per requirement.

When the molten iron is cooled suddenly, it is known as white cast iron

but when it is cooled slowly, it is known as grey cast iron.

Metallurgy of Copper

Copper

occurs in native as well as in combined state. Most common ores of copper are

in form of sulphides, carbonate and oxides.

Sulphide Ores: Copper

Pyrite (CuFeS2) or copper glance Cu2S

Oxide ores: Cuprite

or ruby copper (Cu2O)

Carbonate ores: Malachite

(CuCO3, Cu(OH)2) or azurite 2CuCO3

The

commonest ore used in the extraction of copper is Chalcopyrite (CuFeS2)

also known as Copper Pyrites and other such sulphides.

The

steps involved in extraction of copper

Step1: Crushing

Step2: Concentration

Step3: Reduction

Step4: Bessemerisation

Step5: Refining

Crushing

The

copper pyrite ore is crushed in a big jaw crusher. The output from crusher is

not fine. Therefore, it is passed through a stamping mill. The stamping mill

convert smaller lumps of ore to finely powdered ore.

Concentration

The

process of removal of unwanted impurities (gangue) from the ore is called ore

concentration or ore dressing or ore benefaction. The concentration can be done

either by a physical method or chemical method.

Concentration by physical method (Froth floatation method)

In

physical method no chemical reaction takes place during concentration. The ore

is concentrated using physical property. The finely powdered ore can be

concentrated by froth floatation method. This method is extensively employed

for the preliminary treatment of the minerals especially sulphides. Particle

sized ore particles are mixed with water. The mixture obtained is called

slurry. This is added to the container filled with water and then air jets are

forced into it to create bubbles. The required mineral is repelled by water and

thus gets attached to the air bubbles. As these air bubbles rise up to the

surface with mineral particles sticking to them, these are called froth.

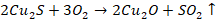

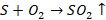

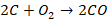

Concentration by chemical method (Roasting)

For

concentration of ore by chemical method, it requires some chemical changes to

ore. This can be done using roasting method. During roasting following chemical

reactions occur

Copper

pyrites decompose to form cuprous and ferrous sulphides

A part

of these sulphides gets oxidised to corresponding oxides

Moisture

is eliminated and impurities like sulphur are removed in their volatile oxides

Reduction

Reduction

of copper ore is done by smelting. The roasted ore is mixed with coke and sand

and is heated in blast furnace in the presence of excess air. Copper Smelting

means that the concentrated ore is heated strongly with silicon dioxide

(silica), calcium carbonate (CaCO3) and air in a furnace. The major

steps in the extraction of copper are

ü Copper

in Chalcopyrite is reduced to copper sulphide.

ü Calcium

carbonate is added as a flux to create the slag.

ü Iron

in Chalcopyrite is removed as iron silicate slag.

ü Most

of the sulphur in Chalcopyrite turns into Sulphur dioxide (SO2).

The

copper extracted from this process is mixed with the slag and is called Matte

Copper due to its texture and appearance. Matte is a mixture of molten Cu2S

+ FeS. This molten matte so produced is then converted to blister copper by Bessemerisation.

Bessemerisation

The

molten metal is then transferred to a Bessemer converter. Bessemer converter is

a furnace made up of steel plates and lined with basic lining of lime or

magnesia. It is mounted on pivot and can be tilted in any position. The furnace

is provided with pipes known as twyers through which sand and hot air is blown

into it. The tuyeres are fitted sufficiently high above the bottom so that the

molten metal drops below the level of twyers and escapes the oxidising action

of the air. FeS is converted to slag. Slag is poured off by tilting converter. Cu2O

is reduced to metallic copper.

After

the reduction is complete, the molten copper is poured into sand moulds. As the

metal solidifies, SO2 escapes and leaves blisters on the surface.

The solid metal thus obtained is called as blister copper which contains 96% to

98% copper. The remaining 2% is iron with small amounts of An, Ni which were

present originally in the ore. This copper can be used in construction of

pipes, boilers, etc. But to conduct electricity copper must be extremely pure.

There blister copper goes to refining stage.

Refining

Refining

of copper can be done in two stages as discussed below to obtain extremely pure

copper. However, either of the stages can be used for refining of copper.

Poling

In this

process, blister copper is melted in a reverberatory furnace in the presence of

air. The molten mass is then stirred with a green log of wood. The green log of

wood produces hydrocarbon gases which reduces cuprous oxide to metallic copper.

This refining reduces copper with 99.2% to 99.6% concentration

Electrolytic refining

The

copper obtained from poling can be concentrated up to 99.9% by electrolytic

refining. However, blister copper can be directly refined using this method.

This is a standard electrolysis setup, where the impure copper (the sample to

be refined) is placed as anode and a thin strip of pure copper is placed as a

cathode.

Impure

or blister copper is about 99% pure when extracted from the ore. Copper metals

can be refined up to 99.99% by electrolytic refining. The anode (positive

electrode) is made from impure copper, and the cathode (negative electrode)

from pure copper. Copper sulphate acidified with sulphuric acid is used as an

electrolyte in this process. By passing electric current, the impure metal

dissolves from the anode into the electrolytic solution. In this phase, copper

sulphate dissociates into Cu++ and SO42- ions.

The positive copper ions, also known as the cations, move towards the cathode,

which is made up of pure copper metal. The metal cations absorb electrons from

the cathode and get deposited on the cathode as Cu atoms. Thus, pure copper is

produced at the cathode.

The

following reactions take place when an electric current is passed through the

electrolytic solution:

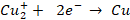

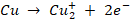

At

cathode:

At

anode:

The

soluble impurities dissolve in the electrolytic solution, while insoluble impurities

can be found at the bottom of the anode. This insoluble impurity is known as

anode mud. In this method, the cathode is coated with graphite as it makes the

separation of pure copper easier.

Properties of copper

Engineering

properties of copper

Copper

is a heavy reddish-brown metal. It gets polished easily and hence used for

making utensils.

ü It

has high melting point and boiling point. Also, it is a very good conductor of

electricity thus making it useful for electrical connections

ü It

is malleable and ductile and can be drawn into wires of small diameter

ü Copper

is next to silver in terms of conductivity to heat and electricity

ü It

casts very well and forms alloys

Chemical

properties of copper

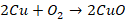

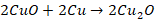

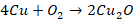

Action of air

Copper

is not attacked by dry air at ordinary temperatures. However, if it is heated

till it becomes red in the presence of air, it forms cupric oxide and on

further heating it forms cuprous oxide.

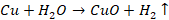

Action of water

Water

at ordinary temperature has no action on copper. However, red hot copper reacts

with steam and form oxide

Action of acid

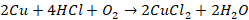

Action of HCl (hydrochloric acid)

Cold

and dilute HCl has no action on copper. Copper reacts with warm dilute HCl in

presence of oxygen to form cupric chloride

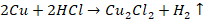

Also,

copper powder dissolves slowly in hot and concentrated HCl with the evolution

of hydrogen

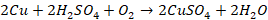

Action of H2SO4 (sulphuric acid)

Cold

and dilute H2SO4 has no action on copper. It dissolves

slowly in hot and diluted H2SO4 in the presence of

oxygen.

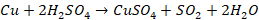

On heating

with concentrated H2SO4, it produces SO2

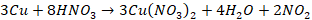

Action of HNO3 (nitric acid)

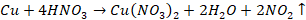

Dilute HNO3

dissolves the metal with the evolution of nitric acid

Concentrated

HNO3 dissolves the metal and gives nitrogen dioxide

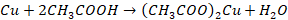

Action of CH3COOH acetic acid

In

presence of air, copper reacts with acetic acid to form cupric acetate

Metallurgy of aluminium

Aluminium

is a soft, silvery-white, corrosion-resistant metal. It is the most abundant

metal in the earth’s crust as it makes up 8% of the crust and it is the third

most abundant element after oxygen and silicon. It occurs widely as constituent

of rocks and soils. Its main ores are:

Oxides: Bauxite (Al2O3.2H2O),

Corundum (Al2O3)

Fluoride: Cryolite

(Na3AlF6)

Silicates: Feldspar (KAlSi3O8),

Mica (KAlSi2O10(OH)2)

Basic sulphates:

Alunite (K2SO4.Al2(SO4)3.4Al(OH)3)

Bauxite

ore is most widely found and hence it is commonly used to extract Aluminium.

Extraction of aluminium

Extraction

of aluminium involves following three steps:

Step1: Purification of Bauxite

Step2: Electrolytic

reduction of alumina

Step3: Refining

of alumina

Purification of bauxite:

Bauxite

ore generally contains ferric oxide and silica as impurities. Dressing of

Bauxite ore is done by crushing and pulverising. Purification method varies

according to the type of impurities present.

ü Baeyer’s

process for the removal of impurities of iron (red bauxite)

ü Serpeck’s

process for the removal of impurities of silica (white bauxite)

ü Hall’s

process for the removal of both iron and silica impurities

Baeyer’s Process

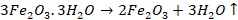

The

powdered bauxite ore is roasted to convert ferrous oxide (FeO) to ferric oxide

(Fe2O3). This roasted ore is then heated with

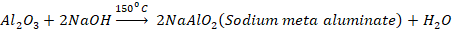

concentrated NaOH under pressure for few hours in autoclave. This process is

referred to as leaching. Aluminium oxide dissolves forming sodium

meta-aluminate, while ferric oxide remains undissolved.

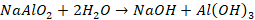

Undissolved

Fe2O3 is removed by filtration. The sodium meta-aluminate

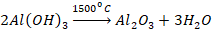

is diluted with water to form a precipitate of aluminium hydroxide Al(OH)3.

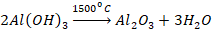

The

precipitate of Al(OH)3 is then filtered out, dried and heated at 1500℃

to get pure alumina

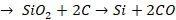

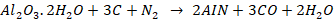

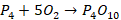

Serpeck’s process

Serpeck

process is a method of purification of bauxite ore containing silica (SiO2)

as the main impurity. When Silica is the main impurity, it is called

white bauxite. The powdered bauxite is mixed with carbon and heated up to 1800℃

and a current of nitrogen is passed, aluminium nitride is obtained.

Aluminium

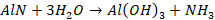

nitride thus obtained is hydrolysed with water to get a precipitate of Al(OH)3.

The

precipitate of Al(OH)3 is filtered, washed and dried.

The

silica present as an impurity in bauxite is reduced to silicon which is volatile

at high temperature. So, it is removed easily.

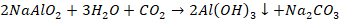

Hall’s Process

This

method is used for the ore having both Fe2O3 and SiO3

as impurities. The powdered ore is bright red heated with sodium carbonate.

Aluminium oxide dissolves to form sodium meta-aluminate while insoluble Fe2O3

and SiO2 are left residue.

The

fused mass is extracted with water and the insoluble Fe2O3

and SiO2 are removed by filtration. The filtrate is then heated to 50o

C to 60o C and a current of CO2 is passed through it and Al(OH)3

is precipitated out.

Al(OH)3

is filtered off, dried and ignited to get pure alumina.

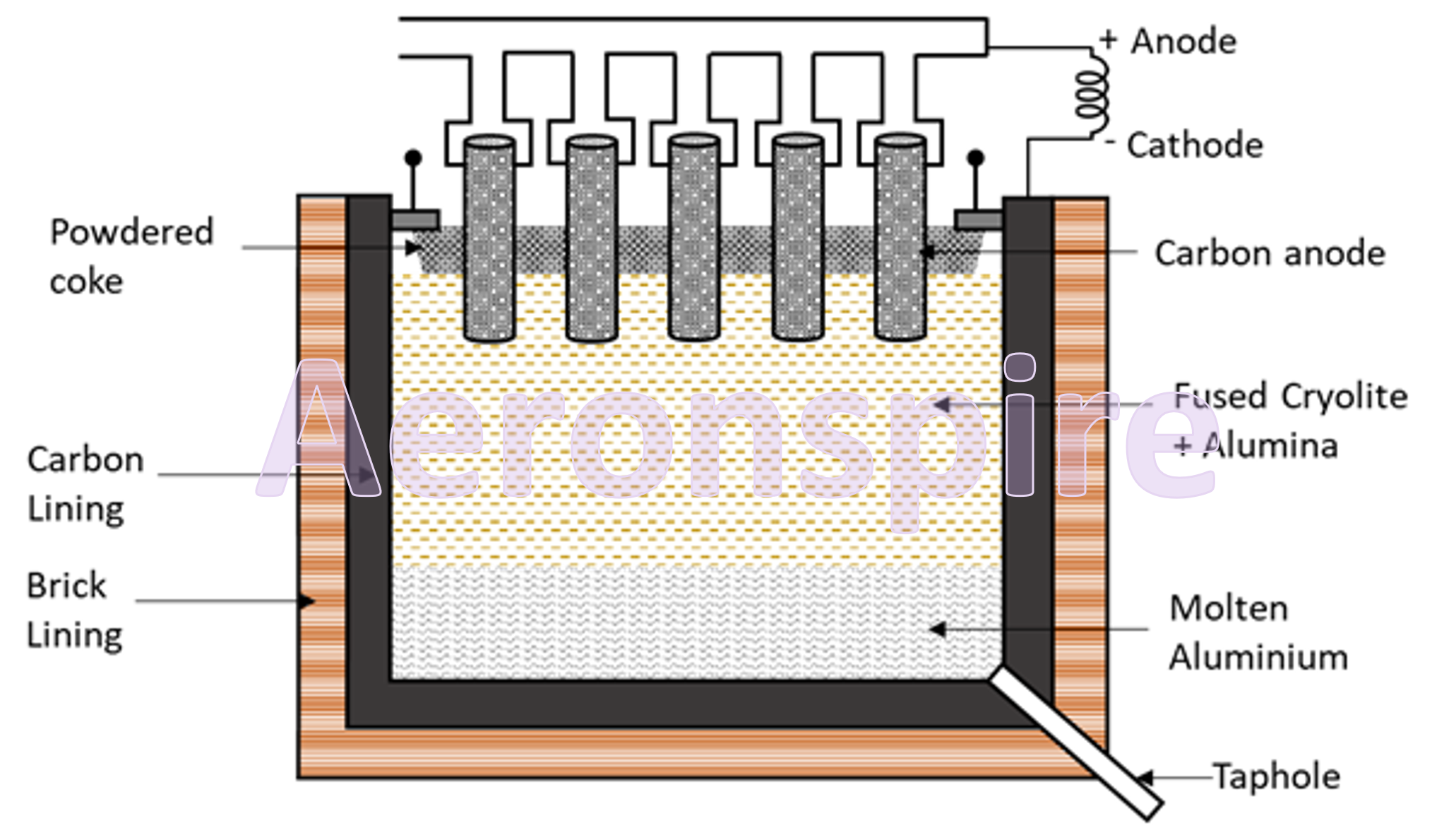

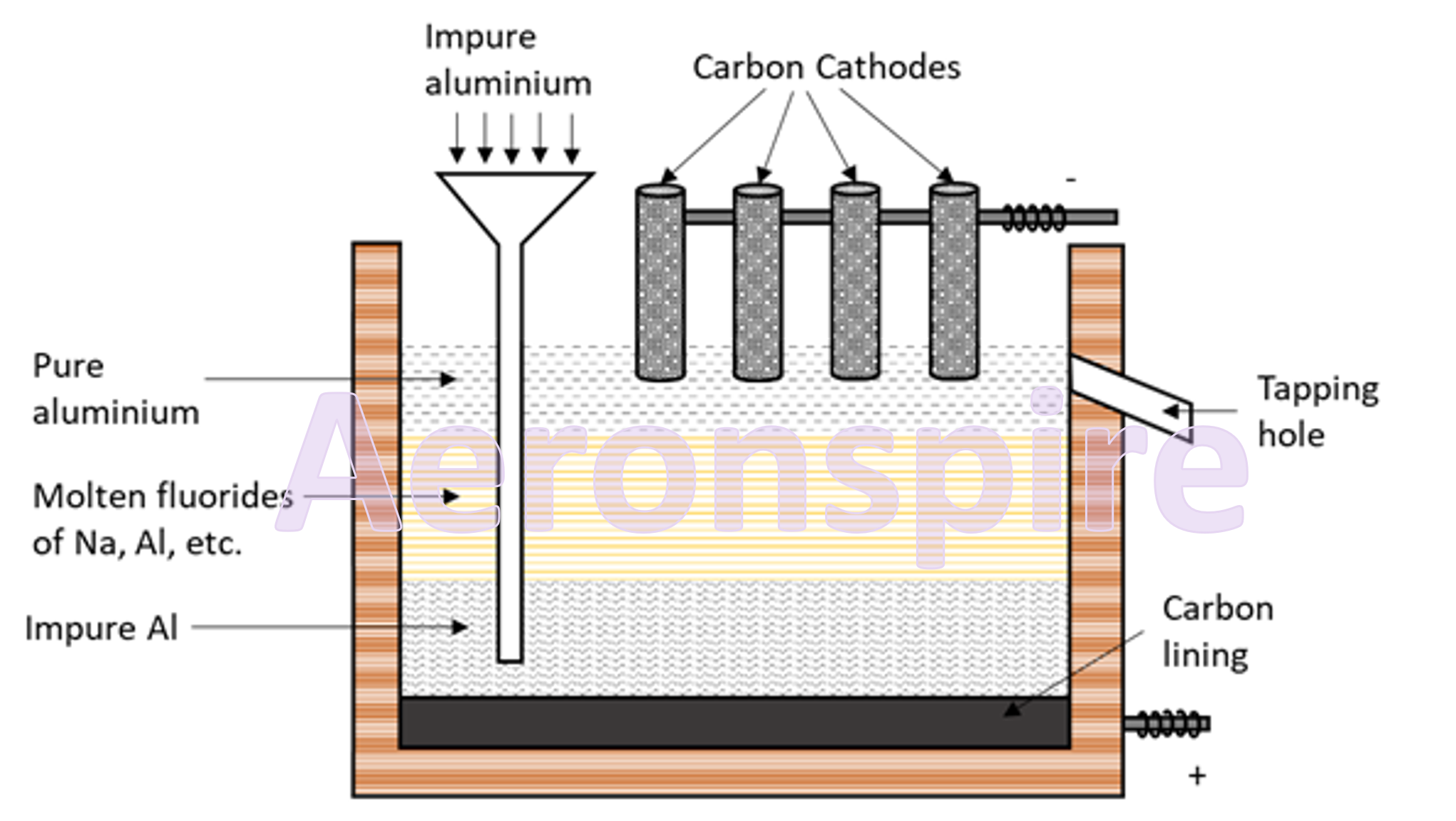

Reduction

Alumina

cannot be reduced to metallic aluminium by carbon, because aluminium has great

affinity for oxygen and thus the reduction of alumina by carbon under ordinary

condition is not possible. Thus, alumina is reduced to aluminium using

electrolytic reduction. However, alumina is a bad conductor of electricity and

has very high melting point. If electrolysis is carried out at 2000o

C, aluminium obtained vaporises. Hall and Heroult overcome these difficulties

by carrying the electrolysis of alumina in the presence of cryolite (Na3AlF6)

which acts as a proper electrolyte. In Hall-Heroults process, pure Al2O3

is mixed with CaF2 or Na3AlF6. This results in

lowering the melting point of the mixture and increases its ability to conduct

electricity. A steel vessel with a lining of carbon and graphite rods is used.

The

carbon lining acts as a cathode and graphite act as an anode. When electricity

is passed through the electrolytic cell which consists of carbon electrodes

oxygen is formed at the anode. This oxygen formed reacts with the carbon of the

anode to form carbon monoxide and carbon dioxide. In this

method of production of aluminium, for every 1 kg of Al produced, approximately

0.5 Kg of carbon anode is burnt. This electrolytic bath is covered with

powdered coke to avoid the oxidation of metal and to avoid the loss of heat.

Heat produced by the current keeps the mass in fusible state. The temperature

of bath is maintained at 900o C – 1000o C. On passing

current, alumina decomposes to aluminium and oxygen

During

the process of electrolysis, Aluminium ions that are positively charged gain

electrons from the cathode and form molten aluminium. Oxide ions lose electrons

at the anode and form molecules of oxygen.

The

molten aluminium sinks to the bottom (cathode) from where it is tapped off from

time to time. Oxygen is liberated at anode, which then combines with carbon

anodes and form CO and CO2. These gases escape through outlet.

At the

cathode:

At the

anode:

The

concentration of alumina falls in the cell below a certain limit, the

resistance of the cell increases and therefore, more current flows through lamp

connected in parallel with cell and it glows. This indicates that alumina is

exhausted and more alumina needs to be added to continue the process.

Refining of aluminium

Aluminium

is further purified by Hoope’s process. The electrolytic cell consists of an

iron box lined inside with carbon. The cell consists of three layers which

differ in specific gravities.

a)

The upper layer is of pure aluminium which acts as cathode.

b)

The middle layer consists of a mixture of the fluorides of Al, Ba and Na.

c)

The lowest layer consists of impure aluminium which acts as anode.

When

electrolysis occurs, current passes through the middle layer and the Al+3

ions migrate from the middle layer towards the cathode where they get reduced

to form Al. The lowermost layer or the anode produces an equal number of Al+3

ions, which move to the middle layer and then to the upper layer where they

form Al.

In this

way all the pure aluminium gets deposited at the uppermost layer and the

impurities are left behind. The aluminium obtained at the end was 99.99% pure.

Properties of aluminium

Physical properties

ü Aluminium

is silvery and lustrous white metal which takes very high polish.

ü Aluminium

is a good conductor of heat and have high melting and boiling point and thus is

used to make utensils

ü Aluminium

is a good conductor of electricity and thus used to make wire

ü It

is malleable and ductile and can be rolled into sheets, foils and wires.

Chemical Properties

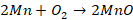

Action

of air

Aluminium

is not affected by dry air and form a thin layer of oxide in moist air. This

prevents aluminium from further corrosion. On heating in air or oxygen, it

burns readily which produces light with the evolution of a huge quantity of

heat.

Action

of water

Pure

aluminium is not affected by pure water. However, impure aluminium is readily

corroded by water containing salts. It decomposes boiling water with the

evolution of hydrogen.

Amalgamated

aluminium Al - Hg reacts most instantly with cold water liberating hydrogen.

Hence it is used as reducing agent.

Action

of acid

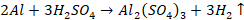

Aluminium

dissolves readily in HCl to form aluminium chloride and liberates hydrogen.

Diluted

H2SO4 reacts slowly with aluminium and liberates hydrogen

Hot and

concentrated H2SO4 liberates SO2 gas with

aluminium

Nitric

acid has no action on pure aluminium

Action

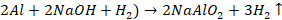

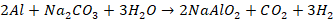

of base

Aluminium

readily dissolves in strong bases like NaOH, KOH forming metal aluminates and

liberates H2 gas.

It

dissolves in hot concentrated solution of Na2CO3 forming

sodium meta-aluminate

Alloys

The

meaning of the term ‘alloy’ is a substance formed from the combination of two

or more metals. Alloys can also be formed from combinations of metals and other

elements. Pure metals have properties like metallic lustre, good electrical

conductivity, high malleability, and ductility. These metals are very soft,

highly chemically reactive. This makes metal useless for engineering purposes.

To make metal useful, desired properties are incorporated by mixing it with

other compounds. To impart certain properties to metals, or in order to

strengthen some of their existing properties, certain other metals/elements can

be added to the metals in specific ratios to form alloys. For example, pure

aluminium is a relatively soft metal. Pure copper is also quite soft. However,

when aluminium is alloyed with copper, the strength of the resulting alloy is

far greater than that of its parent metals.

Properties of alloy

An

alloy’s properties are distinct from those of the individual metals from which

it is produced. Some properties of alloys are given below.

ü An

alloy is a homogeneous mixture of two or more elements one of which must be a metal.

ü Alloys

are harder than their constituent metals.

ü Alloys

are more resistant to corrosion than pure metals.

ü Alloys

are more durable than the metals they are made from.

ü The

electrical conductivity of alloys is lower than that of pure metals.

ü Alloys

have a lower melting point than the metals from which they are made.

ü Alloys

have greater ductility than their constituent metals.

Preparation of alloys

An

alloy can be prepared by any of the following method

(a) Fusion

(b) Electro deposition

(c) Compression

(d) Reduction

(a) Fusion

This

method uses alloying elements in a fixed proportion and fuses them together in

a refractory melting pot or in a brick-lined crucible. The component metal with

a higher melting point is melted first and then the other component with a

lower melting point is added to the melt. Both metal components are mixed well

and allowed to melt further. The molten mass is covered by powdered Carbon to

avoid oxidation of the molten alloy components because they are very reactive

to the surrounding atmospheric oxygen. The resulting molten mass is allowed to

cool at room temperature. In the production of brass, an alloy of copper and

zinc is melted first and then required quantity of zinc is added to it which

melts immediately. The molten mass is stirred, covered with charcoal, and

allowed to cool to avoid oxidation of copper and zinc.

(b) Electro deposition

This

method involves simultaneous deposition of different component metals from the

electrolytic solution containing their salts solution mixture by passing direct

electricity. Brass can also be obtained by electro deposition method. The

electrolysis of mixed solution of copper and zinc cyanides dissolved in

potassium cyanide is carried out to obtain brass.

(c) Compression

Alloy

can also be made by method of compression. In this method, two or more metal

powders are mixed and compressed under a high pressure in a mould. The moulded

article is then heated to a temperature just below the melting point of an

alloy. Due to this, tiny particles of metal are firmly welded to one alloy. An

alloy of lead and tin known as solder alloy is made by this method. Wood’s

metal is an alloy of lead, tin, bismuth, and cadmium is also made by this

method.

(d) Reduction

The

alloy is obtained by the reduction of a suitable compound, generally oxide of

one component metal in the presence of the other component metal. The component

metal oxide is reduced to metal in the presence of other metal. Aluminium

bronze is alloy which is prepared by reducing aluminium oxide in the presence

of copper in an electric furnace.

Need of alloys

To improve the hardness of metal: Pure metals are generally soft. But when

the metal is alloyed with another metal or non-metal, its hardness is

increased. Pure gold and silver are soft and hence cannot be used. But to make

it useful, it is hardened by addition of small amount of copper. Similarly,

pure iron is very soft and cannot be used for any engineering purposes. The

iron is hardened by addition of small amount of carbon. The resultant iron is

nothing but steel.

To lower the melting point: When an alloying element is added to base

metal, it acts as an impurity. The impurity lowers the melting point of base

metal. Wood’s metal is an alloy of bismuth, lead, tin, and cadmium has melting

point of 70o C.

To increase the tensile strength:

While a metal is alloyed, it increases its tensile strength. For example, when

iron is alloyed with 1% of carbon, it increases its tensile strength by 10

times.

To increase the corrosion resistance: The metals in pure form are highly

reactive. They get easily corroded with atmospheric air and moisture. But if

metal is alloyed, it resists corrosion. For example, iron gets easily corroded

in air and moisture, but its alloy steel resists corrosion.

To get good casting: Pure

metals contract on solidification so it becomes difficult to cast fine

impression. Hence, in order to get good castings, metals must be alloyed. Alloy

expands on solidification.

To reduce malleability and ductility:

Pure metals are highly malleable and ductile. Pure metals change their shape

even when very small force is applied. Its malleability and ductility can be

reduced by making it alloy.

To modify chemical activity: Pure metals are highly reactive and can

easily react with other elements. But when it is alloyed with other element it

becomes less reactive. For example, sodium is highly reactive but when alloyed

with mercury (sodium-amalgam (Na-Hg)) it becomes less reactive.

Classification of alloys

Alloys

are generally classified in two classes

Ferrous

alloys

Non-

ferrous alloys

Ferrous alloys: Ferrous

alloys are those alloys which contains iron as its main component. The term

‘ferrous’ has been derived from the Latin term ‘ferrum’ meaning iron. The most

common ferrous alloys are steel.

There

are Different Forms of Ferrous Metals Available in the Market. Some of the

Major Types and Their Characteristics are Stated below:

Stainless

Steel – Resistance to Corrosion

Cast

Iron - Hard, brittle, strong, self-lubricating,

economical

Mild

Steel – Ductile, tough, high tensile strength. Due to

low carbon content, it cannot be toughened and tempered. It should only be case

hardened.

High

Carbon Steel - The hardest of the carbon steels. Tough

and malleable but less ductile.

Methods of steel making

Steel

is manufactured by blowing hot air or oxygen through molten cast iron whereby

impurities are oxidized and removed as volatile gases. Small amount of carbon

is added to the pure molten iron to make steel of required strength and

malleability. Steel can be made by any of the following methods: Electric

process, Bessemer process, Open hearth process and duplex process. These are

old methods of making steel. New methods include Kaldo process and

Linz-Donawitz process.

Bessemer Process

The

Bessemer process was the first inexpensive industrial process for the mass

production of steel from molten pig iron before the development of the open

hearth furnace. The key principle is removal of impurities from the iron by

oxidation with air being blown through the molten iron. In this method, a

furnace called Bessemer converter is used. It is a pear or egg shaped vessel

constructed by using steel plates. It is supported on side arms called trunnion

to orient it in different angles. Twyers are provided at the bottom and hence

it is also known as bottom-blown converter. From inside it is lined with

refractory lime bricks or silica bricks. When acidic impurities are to be

removed, basic lining such as dolomite (CaCO3.MgCO3) is

used and the process is referred to as basic Bessemer process. When basic

impurities need to be removed, acidic lining of silica is used and the process

is referred to as acid Bessemer.

Acid Bessemer process

In this

process the converter is lined with silicious refractory material. The

converter starts in horizontal position and charged with about 60 tonnes of

molten cast iron at 1200o C. Then it is turned to vertical position and

a hot blast of air blown from the twyers. Impurities get oxidized and

temperature rises to 1900o C. The reactions taking place in

converter are as follows:

The

oxides of silicon and manganese combine to form a slag of manganese silicate

A

little amount of iron is also oxidized to ferric oxide, but it gets readily

reduced by carbon present in the cast iron.

Ferric

oxide formed above also oxidizes manganese and silicon to their respective

oxides

These reactions

are then observed by the colour of burning waste gases. Carbon monoxide

produced burns at the mouth of the converter with a blue flame and orange-red

tinge, throwing out shower of sparks. When whole carbon is oxidized, the blue

flame suddenly dies down. When the blue flame dies, a calculated amount of Fe, Mn,

and C is added.

Blast

of air is passed; mass is mixed well. Molten iron contains dissolved gases such

as O2, N2 and CO2 which create blow holes or

gas bubbles in castings and defects are created. This is then followed by the

addition of aluminium. Aluminium reacts with these gases and removes them as

slag.

Basic Bessemer

This

process is used to treat cast iron containing phosphorus. In this process, the

converter is lined with magnesia and lime prepared by calcinations of dolomite (CaCO3.MgCO3).

Some limestone is added into the converter. Molten cast iron from blast furnace

is then run into the converter and the blast is continued. Carbon, sulphur, and

manganese are oxidized first as usual, but if the blast is continued even after

the flame sinks down, then the phosphorus forms phosphorus pentoxide.

The

phosphorus pentoxide thus formed, combines with lime to form a basic slag,

containing calcium phosphate

After

complete removal of slag, required amount of carbon is added and the product is

thoroughly mixed in presence of air.

Merits of Bessemer Process

ü This

process is useful for rapid production of steel.

ü Cost

of operating process is low

ü No

extra fuel is required as molten cast iron is directly taken to converter from

blast furnace.

Demerits of Bessemer Process

ü Steel

produced is of inferior quality

ü Approx

15% of iron is lost in slag

ü Process

is not continuous and charging is tedious

Linz-Donawitz Process

LD is

named after the two places of Austria namely, Linz and Donawitz where the

process was first formed. It is a refining process which is done through an LD

convertor or LD vessel. LD is also known as Basic Oxygen Process. The furnace

is an egg-shaped steel vessel, sealed from bottom and supported on the side

arms called trunnions. It is lined from inside with basic lining of magnetise

or limestone. At the top, it also has an oxygen lance made up of concentric

steel tubes with a tip of copper.

Charging: Five materials are required

for this purpose. The converter is charged with cast iron, scrap, limestone,

coolants, pure and dry oxygen.

Blowing: Once the charging is done then

the converter is rotated upright in the vertical position and the lance is lowered

to the position of blowing. O2 is then turned on for around 20

minutes, at a pressure of 9 to 11 atoms that raises the temperature and

impurities are burned off.

Sampling: for analysis, slag and metal

samples can be taken and the temperature of the bath needs to be measured by

immersion of thermocouple.

Tapping: the

molten steel is tapped in the ladle if the tapping temperature is in the

required range. Ladle is used to make deoxidizers and alloying additions. It

has a tap-to-tap time of 40-50mins.

Slag off: after

tapping steel into the ladle and putting the vessel upside down tapped the

remaining slag into the slag pot.

Merits

ü It

is rapid process with high productivity.

ü Energy

needed is comparatively low.

ü Steel

produced is of superior quality.

ü Molten

cast iron and scrap can be used directly.

Composition, properties, and application of plain carbon steel

Plain

carbon steel is an alloy of iron and carbon where the amount of carbon ranges

from, 0.015% to 2%. Carbon steel is by far the most widely used kind of steel.

The properties of carbon steel depend primarily on the amount of carbon it

contains. In fact, there are 3 types of plain carbon steel and they are low

carbon steel, medium carbon steel, high carbon steel, and as their names

suggests all these types of plain carbon steel differs in the amount of carbon

they contain. Indeed, it is good to precise that plain carbon steel is a type

of steel having a maximum carbon content of 1.5% along with small percentages

of silica, sulphur, phosphorus and manganese.

Plain

carbon steels are further subdivided into four groups:

Low carbon steels (carbon: 0.05% <carbon< 0.30%):

Often called mild steels, low-carbon steels are the most commonly used grades.

They machine and weld nicely and are more ductile than higher-carbon steels.

Use: It is used for thin soft

wires, ropes, chains, tubes, etc.

Medium carbon steels (0.30% < carbon < 0.60%):

Increased carbon means increased hardness and tensile strength, decreased

ductility, and more difficult machining.

Use: It

is mainly used in rail roads, wheels, axles, crane hooks, etc.

High carbon steels (0.6% < carbon < 0.90%):

these steels can be challenging to weld. Preheating, post heating (to control

cooling rate), and sometimes even heating during welding become necessary to

produce acceptable welds and to control the mechanical properties of the steel

after welding.

Use: It is used for making tools,

drills, knives, hammers, etc.

Very high carbon steels (0.9% < carbon < 1.5%):

very high-carbon steels are used for hard steel products such as metal cutting

tools and truck springs. Like high-carbon steels, they require heat treating

before, during, and after welding to maintain their mechanical properties.

Use: It

is mainly used for preparation of cutting tools, blades, saws, etc.

Limitations of plain carbon steel:

ü There

cannot be strengthening beyond about 100000 psi without significant loss in

toughness (impact resistance) and ductility.

ü Plain-carbon

steels have poor impact resistance at low temperatures.

ü Plain-carbon

steels have poor corrosion resistance for engineering problems.

ü Plain-carbon

steel oxidises readily at elevated temperatures.

Effects of various alloying elements on steel

Steel

is alloyed with various elements to improve physical properties and to produce

special properties such as resistance to corrosion or heat. Steel is alloyed

with number of elements such as Nickel, Silicon, Chromium, etc. Specific

effects of the addition of such elements are outlined below:

Some

important alloy steels have been listed:

|

Name

|

Composition

|

Properties

|

Uses

|

|

Molybdenum

Steel

|

0.3%

to 3% Mo

|

Increases

strength, hardness, hardenability, and toughness and strength even at high

temperatures. It improves machinability and resistance to corrosion.

|

Axis and

cutting tools

|

|

Nickel

steel platinate

|

46%

Ni

|

Increases

strength and hardness without sacrificing ductility and toughness. High

co-efficient of expansion

|

Wire

scales, electric bulbs, etc.

|

|

Chrome

steels

|

2%

to 4% Cr

|

Increases

tensile strength, hardness, hardenability, toughness, resistance to wear and

abrasion

|

Ball

bearings, cutting tools, etc.

|

|

Manganese

steels

|

6%

to 15% Mn

|

It

increases tensile strength, hardness, hardenability and resistance to wear.

|

Crushing

Machine, helmet, railroad, etc.

|

|

Stainless

steel

|

12%

to 20% Cr, 8% Ni

|

Resistant

to corrosion, non-magnetic, brittle.

|

Cutlery,

utensils, surgical appliances

|

|

Nickel

Steel

|

2.5%

to 5% Ni

|

Hard,

resistant to corrosion

|

Wires,

cables, gears, etc.

|

|

Cobalt

steel

|

Upto

35% Co

|

High

magnetism, hard, resistant to corrosion

|

High

speed tools and permanent magnets

|

|

Silicon

steel

|

Upto

15% Si

|

Extremely

hard, resistant to acids

|

Pumps,

pipes carrying acids, transformers

|

|

Tungsten

steel

|

15%

to 20% W

|

Increases

strength, wear resistance, hardness and toughness. Tungsten steels have

superior hot-working and greater cutting efficiency at elevated temperatures.

|

High

speed machine, drilling tools, cutting tools, etc.

|

|

Vanadium

steel

|

3.5%

to 5% V

|

Increases

strength, hardness, wear resistance and resistance to shock impact. It

retards grain growth, permitting higher quenching temperatures

|

Cutting

tools

|

Non-ferrous alloys

Non-ferrous

metals are alloys or metals that do not contain any appreciable amounts of iron.

Non-ferrous alloys are formed by mixing atoms of transition metal other than

iron with a non-transition metal. Example: Brass is an alloy of copper and

zinc. It does not contain iron and hence it is non-ferrous alloy. Several non-ferrous

alloys are discussed below:

Copper Alloys

ü Alloys

which contain copper as base metal are known as copper alloys.

Properties of copper alloy

ü Copper

alloys are generally reddish in colour.

ü Its

specific gravity is 8.93 and hence it is a heavy metal.

ü It

has high melting and boiling point.

ü Copper

alloys are generally good conductor of electricity and heat

ü Copper

alloys are malleable, tough and ductile

ü Copper

alloys are resistant to corrosion

Composition of copper alloy

|

Name

|

Composition

|

Property

|

Application

|

|

Brass

|

66%

Cu

34%

Zn

|

Bright gold

appearance. Highly ductile, low friction and resistant to corrosion

|

Bells,

horns, utensil, jewellery

|

|

Bronze

|

88%

Cu

12%

Tin

|

Hard and brittle.

Low metal to metal friction. High resistance to corrosion from saltwater

|

Used

in sculpture, musical instruments

|

|

Nickel

silver or German silver

|

18%

Ni

62%

Cu

20%

Zn

|

Silver

white appearance Highly lustrous, tough and corrosion resistance

|

Cutlery,

marine fittings, heating coils

|

Aluminium alloys

An

aluminium alloy is an alloy in which aluminium (Al) is the predominant metal.

The typical alloying elements are copper, magnesium, manganese, etc.

Properties of aluminium alloy

ü Aluminium

alloys are generally bluish white

ü Its

specific gravity is 2.7 and hence it is a light metal

ü It

has comparatively low melting point and high boiling point

ü It

is malleable and ductile

ü Aluminium

alloys are generally good reflector of light

Composition of aluminium alloy

|

Name

|

Composition

|

Property

|

Application

|

|

Duralumin

|

94%

Al

4%

Cu

1%

Mg

0.5-1%

Mn

|

Whitish

appearance, resistant to corrosion, hard, good conductor of heat and

electricity

|

Wire,

bar, rods, wheels, aircraft fittings, etc.

|

|

Magnalium

|

95%

Al

5%

Mg

|

Light

weight and brittle. Poor castability and good machinability

|

Suitable

for making aircraft and automobile parts.

|

Solder alloys

Solder

alloy is a metallic material that is used to connect metal workpieces. Solder

alloys are generally alloys of lead and tin and has low melting point. The

solder alloy becomes softer as the percentage of lead increases and harder as percentage

of tin increases. Solder alloys easily adhere to the metallic surface.

Some more alloys

|

Name

|

Composition

|

Properties

|

Uses

|

|

Soft

solder

|

37%-67%

Lead

31.60%

Tin

0.12%

Stibium

|

Melt

at low temperatures. Percentage of lead is more and hence it is a soft solder

|

Used

for soldering electrical connections.

|

|

Tinman’s

solder

|

66%

Tin

34%

lead

|

It

melts at 180o C. Percentage of lead is less and hence it is a hard

solder

|

Used

for soldering tin articles

|

|

Plumber’s

solder

|

67%

lead

33%

tin

|

Superior

wetting and capillary filling characteristics

|

Used

in making wiped joints and seams

|

|

Brazing

alloys

|

92%

tin

5.5%

lead

2.5%

Copper

|

It

melts at comparatively higher temperature

|

Generally

used for steel joints.

|

|

Rose

Metal

|

50%

Bismuth

25%-28%

lead

22-25%

tin

|

It

is a fusible alloy. Very low melting point

|

Used

for making fire alarms, dental works, automatic sprinkler system

|

|

Wood’s

metal

|

50%

Bismuth

26%

lead

12.5%

Tin

12.5%

Cadmium

|

Very

low melting point. It is very dense and easily fusible

|

Joining

two metallic parts, fire alarms, electric fuse wires.

|